grrr_arrghh

New Member

Hi.

I have a case fan, and wanted to make my own speed controller for it (I refuse to buy the opverpriced poser-ish drvie bay fan controllers, when I could make it myself).

I look in some catalogues, and you seem to be able to buy speed reducers which drop the voltage down to about 7v.

So I think, "Ah ha", speed is determined by voltage.

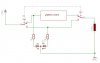

So I rig up a simple potential divider, and drop the voltage of the supply down a few volts, and the fan stops completly. Working my way up from this voltage, I increased it until the fan started spinning. It spun alot slower, and I then worked out what voltage this would be. Assuming that the supply was exactly 12v, I would have been giving the fan 11.97v

How come my fan almost stops when I drop the supply by only 0.03v???!!!??? I don't understand it.

Ok, so maybe my "voltage controlls speed" theory was wrong. What does control the speed of computer fans?

Thanks a lot

Tim

I have a case fan, and wanted to make my own speed controller for it (I refuse to buy the opverpriced poser-ish drvie bay fan controllers, when I could make it myself).

I look in some catalogues, and you seem to be able to buy speed reducers which drop the voltage down to about 7v.

So I think, "Ah ha", speed is determined by voltage.

So I rig up a simple potential divider, and drop the voltage of the supply down a few volts, and the fan stops completly. Working my way up from this voltage, I increased it until the fan started spinning. It spun alot slower, and I then worked out what voltage this would be. Assuming that the supply was exactly 12v, I would have been giving the fan 11.97v

How come my fan almost stops when I drop the supply by only 0.03v???!!!??? I don't understand it.

Ok, so maybe my "voltage controlls speed" theory was wrong. What does control the speed of computer fans?

Thanks a lot

Tim