Mosaic

Well-Known Member

Hi all:

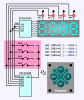

I'm a bit concerned about driving a strobed 4 digit 7segment common cathode from a 16f882 pic.

The Display specs says a 25mA drain, but does that mean PER Digit or altogether?

With a strobe I have to ramp up the current from the PIC to keep the brightness.

I see mentioned in texts to use an 82ohm instead of the usual 330ohm for a single LED, due to the 4x time strobe.

Anyone done this ? What is the real total current pulled from the pic?

I'm a bit concerned about driving a strobed 4 digit 7segment common cathode from a 16f882 pic.

The Display specs says a 25mA drain, but does that mean PER Digit or altogether?

With a strobe I have to ramp up the current from the PIC to keep the brightness.

I see mentioned in texts to use an 82ohm instead of the usual 330ohm for a single LED, due to the 4x time strobe.

Anyone done this ? What is the real total current pulled from the pic?