Hey there,

First im not an electronics wizard just a tinkerer that likes to fix things, so please be patient with my ignorance

I have an AVR that uses a toroidal transformer and a Servo motor to stabilize the voltage. Now if it was new all would be well, but this sad little thing has seen some battle and i thought as a small learning project i would try and restore it. I know i could buy a new one but i just feel it would make me happy to get it working again.

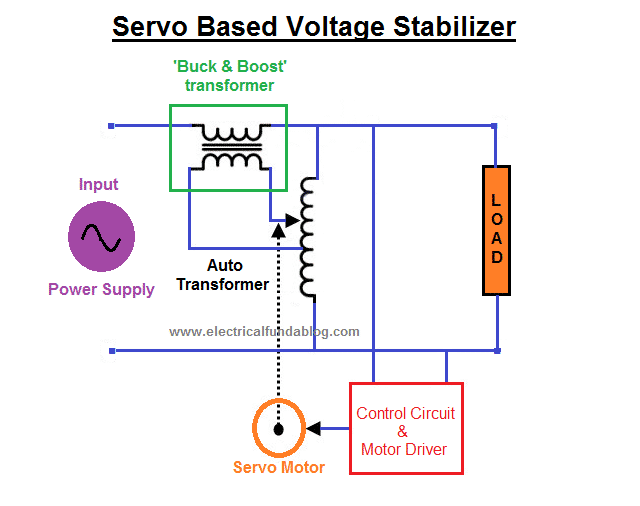

So...i did some research on different types of AVR and a usual diagram is the one below

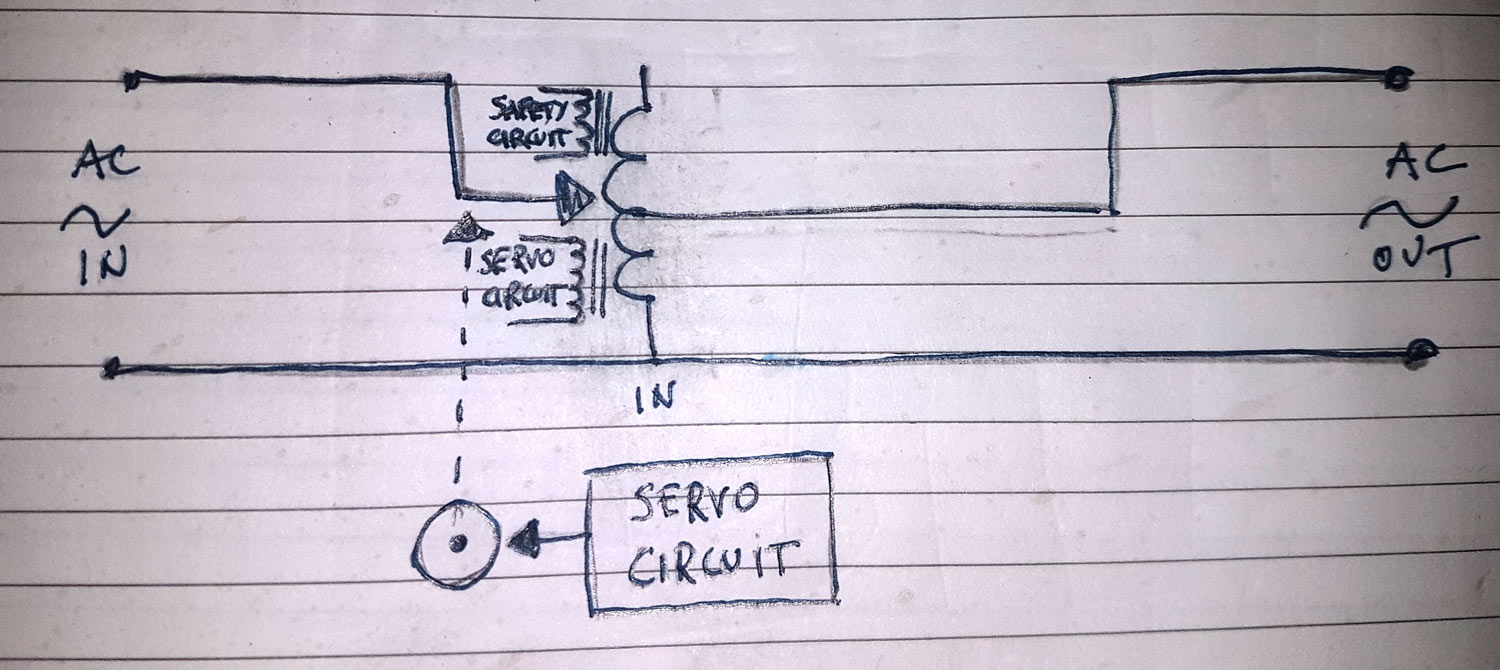

Mine however lookes like this

I know the servo circuit part of the AVR doesn't work (motor works fine on 12v) so it's basically just upping or lowering the voltage if I move the arm over the coil. So the boosting and Bucking seems to work. (I've omitted the "safety circuit" and some switches and Voltmeters in the diagram for simplicity)

Now to the help part...

The person i got it from had made some fixes to it just to make it work so i don't know for sure if he has changed how the wiring was and im trying to understand and if i can, fix it of course.

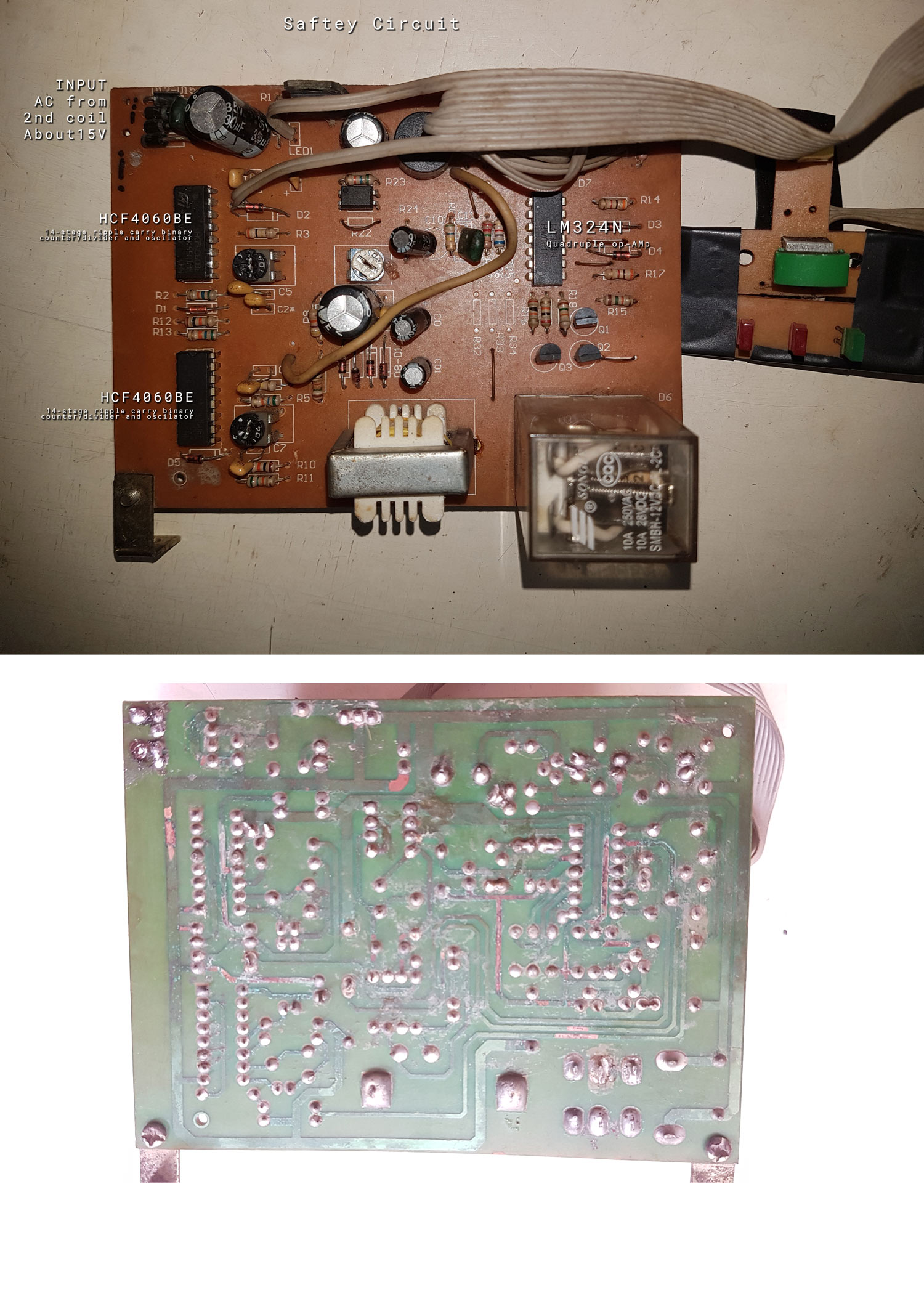

The Safety circuit below only had one input from the secondary coil from the big transformer at about 15v and then strangely it had the phase AC wire (direct from mains) wound once around the right side pillar of the small transformer and then it went to the big transformer primary winding. I'm trying to understand if it is just some anchor point for the cable he used, or it actually does some sensing that way? when powering on the AVR the relay switches on after a few seconds and the LEDs show its on, so it seems the delay/timer works and displays it ok on the leds

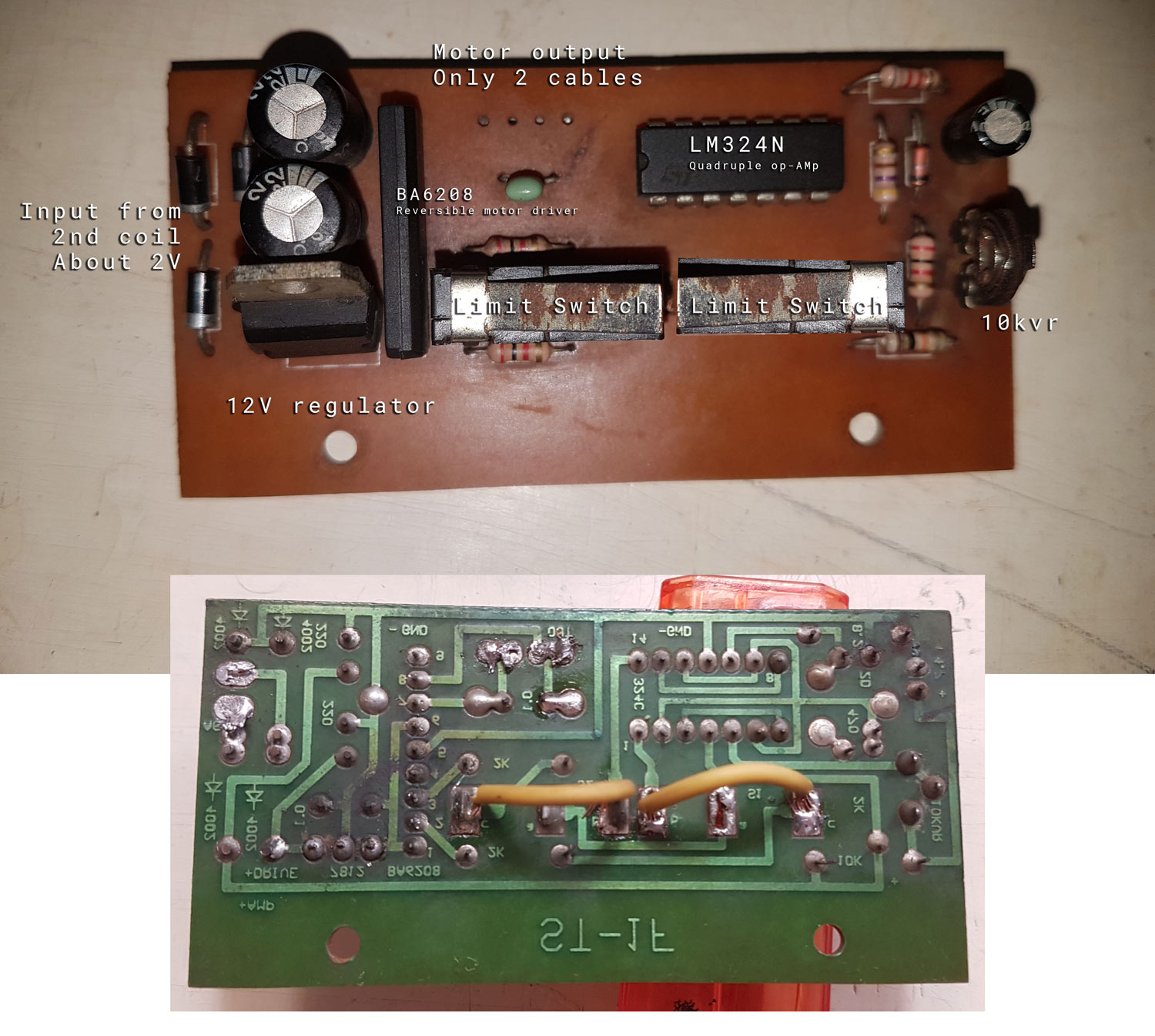

Now the servo motor control circuit i think is broken or not very happy. One of the limit switches was broken in half (ive photoshopped in the missing right one)

This circuit also only had one input from a secondary coil and it was just around 2v which must be either wrongly changed by someone or used as something else i totally dont understand. I did try and use the Safety Circuits input on this as i guess they use the same rectifier components an it uses the voltage difference to somehow control the servo....what i am trying to find out is.... does it, the circuit make any sense or did the previous owner just jerry-rig it to statically raise the voltage and moved around the inputs for some reason..? what do you think?

I've ordered a new motor driver IC and the other as well just in case. I only got 8v on the BA6208 output when it had 12v powering it so maybe it somehow blew..

Anyhow if you have come this far , thank you for giving me your time and hope you have a great New Years EVE 2020!! If you have any insight at all please let me know anything would be helpful.

thanks

Andy

First im not an electronics wizard just a tinkerer that likes to fix things, so please be patient with my ignorance

I have an AVR that uses a toroidal transformer and a Servo motor to stabilize the voltage. Now if it was new all would be well, but this sad little thing has seen some battle and i thought as a small learning project i would try and restore it. I know i could buy a new one but i just feel it would make me happy to get it working again.

So...i did some research on different types of AVR and a usual diagram is the one below

Mine however lookes like this

I know the servo circuit part of the AVR doesn't work (motor works fine on 12v) so it's basically just upping or lowering the voltage if I move the arm over the coil. So the boosting and Bucking seems to work. (I've omitted the "safety circuit" and some switches and Voltmeters in the diagram for simplicity)

Now to the help part...

The person i got it from had made some fixes to it just to make it work so i don't know for sure if he has changed how the wiring was and im trying to understand and if i can, fix it of course.

The Safety circuit below only had one input from the secondary coil from the big transformer at about 15v and then strangely it had the phase AC wire (direct from mains) wound once around the right side pillar of the small transformer and then it went to the big transformer primary winding. I'm trying to understand if it is just some anchor point for the cable he used, or it actually does some sensing that way? when powering on the AVR the relay switches on after a few seconds and the LEDs show its on, so it seems the delay/timer works and displays it ok on the leds

Now the servo motor control circuit i think is broken or not very happy. One of the limit switches was broken in half (ive photoshopped in the missing right one)

This circuit also only had one input from a secondary coil and it was just around 2v which must be either wrongly changed by someone or used as something else i totally dont understand. I did try and use the Safety Circuits input on this as i guess they use the same rectifier components an it uses the voltage difference to somehow control the servo....what i am trying to find out is.... does it, the circuit make any sense or did the previous owner just jerry-rig it to statically raise the voltage and moved around the inputs for some reason..? what do you think?

I've ordered a new motor driver IC and the other as well just in case. I only got 8v on the BA6208 output when it had 12v powering it so maybe it somehow blew..

Anyhow if you have come this far , thank you for giving me your time and hope you have a great New Years EVE 2020!! If you have any insight at all please let me know anything would be helpful.

thanks

Andy

Last edited:

Mine also lacks the built in fan the branded one has. That leads me to the conclusion more things might be different. But I did however email OMNI customer support a while ago and asked if they would be willing to send me the wiring diagram, although I doubt it...

Mine also lacks the built in fan the branded one has. That leads me to the conclusion more things might be different. But I did however email OMNI customer support a while ago and asked if they would be willing to send me the wiring diagram, although I doubt it...