Quoting myself:

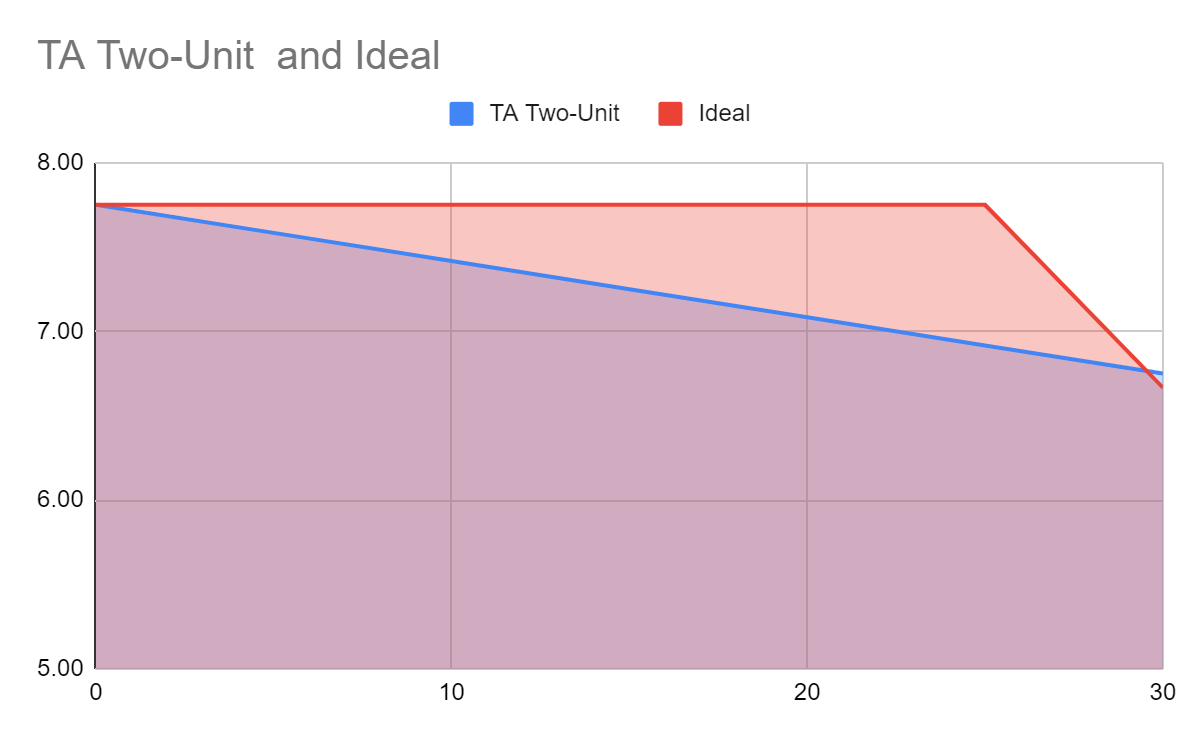

Taking the illustration (above) for example, the regulator is limiting this generator to roughly 30A x 6.75V = ~200 Watts load. But, if you back up to 15A it is capped to 7.25V which is only ~109 watts. Why not stay at 7.75V x 15A = 116 watts? It could stay at 7.75V until 200W/7.75V = ~26A, and then drop off steeply to stay in a 200W envelope. From 26A, it would drop at a slope of

I think this has the potential to squeeze quite a few more coulombs out of the old generator without danger of overloading it.

I'm also thinking that the regulator should be customizable for a particular generator and battery. Two data points should be enough characterize it: unloaded charging voltage, and generator wattage rating.

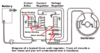

After studying this some more, I've come to understand that this is not the ideal. Rather, this declining characteristic curve is just the best they could do with a two-unit regulator. To protect generator against overloading, the regulator lowers the voltage supplied by the generator as the current increases. But this curve is only linear because one relay has to do two jobs: limiting voltage and current simultaneously. (BOSCH also made a better, more expensive, 3-unit regulator, but not for the VW).

...

I'm thinking that the ideal is to get as close as possible to the regulator curve illustrated above. 7.5 volts at 0 amps, declining to 6.65 at 30 amps.

...

Taking the illustration (above) for example, the regulator is limiting this generator to roughly 30A x 6.75V = ~200 Watts load. But, if you back up to 15A it is capped to 7.25V which is only ~109 watts. Why not stay at 7.75V x 15A = 116 watts? It could stay at 7.75V until 200W/7.75V = ~26A, and then drop off steeply to stay in a 200W envelope. From 26A, it would drop at a slope of

(6.75 - 7.75) / (30 - 26) = -1 V / 4A

So, we get something like this:I think this has the potential to squeeze quite a few more coulombs out of the old generator without danger of overloading it.

I'm also thinking that the regulator should be customizable for a particular generator and battery. Two data points should be enough characterize it: unloaded charging voltage, and generator wattage rating.