RCinFLA

Well-Known Member

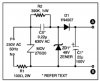

The large ripple voltage on 100 uF causes it to overheat. Electrolytics do not like large ripple voltage. The ballast cap approach works but there is a potential problem with 'bouncing' the A.C. either by plug-in or switch. If the AC is momentarily interrupted by contact bounce the ballast cap charge may add to the newly applied AC peak creating a current surge to LED's. Besides filtering some of the 100 Hz ripple to LED, the primary reason to have the cap across the LED is to absorb the potential bounce spike. The 100 to 200 ohm resistor should be between rectifier and electrolytic to help limit the current spike on contact bounce. Using a higher voltage electrolytic will help a bit on the electrolytic ripple issue.