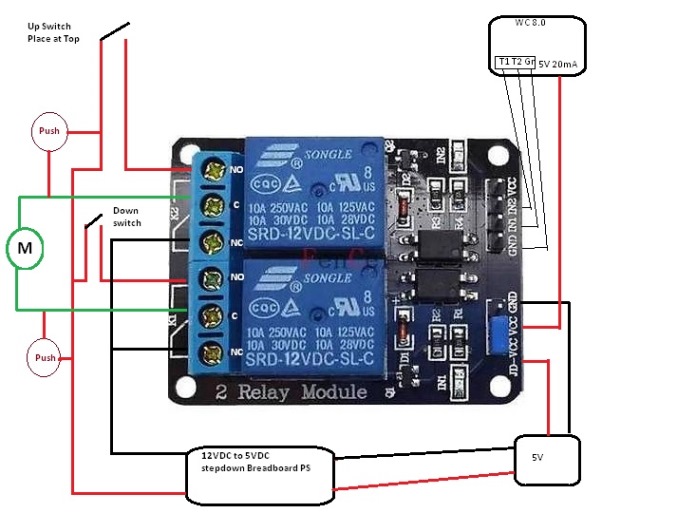

Since I have so far made a disaster of my DIY board to control a 12vdc motor bi-directionally, I have made the below drawing using a 2 relay module.

The module will be controlled with a WebController 8.0 uC giving 5v and 20ma, the motor will draw 10A full load. Though, it will only pull a small plexi glass door, so the load should never max out.

In the drawing are two switches - these are limiter switches when door travels to full up or full down position.

Not only does the uC control the motor with limiting switches, , but I need one additional component - two push buttons at the site of the door/ motor which will allow local activation of the motor, without the use of the itnernet/ LAN.

I beleive the below drawing would work, with one caveat as I can see it (in my very limited electronics knowledge): If I push one of the buttons to activate the door and the uC is activating the other relay at the same time, I would essentially have 2 hot wires goign to the motor. I can't figure out any failafe for this.

In review, I obviously did the drawing wrong at the PS - Bottom left black and red lines should originate from a 12VDC PS, then divert up to relay and right to 12VDC to 5VDC converter module

Any ideas (other than scrapping the project which I am not willing to do)?

The module will be controlled with a WebController 8.0 uC giving 5v and 20ma, the motor will draw 10A full load. Though, it will only pull a small plexi glass door, so the load should never max out.

In the drawing are two switches - these are limiter switches when door travels to full up or full down position.

Not only does the uC control the motor with limiting switches, , but I need one additional component - two push buttons at the site of the door/ motor which will allow local activation of the motor, without the use of the itnernet/ LAN.

I beleive the below drawing would work, with one caveat as I can see it (in my very limited electronics knowledge): If I push one of the buttons to activate the door and the uC is activating the other relay at the same time, I would essentially have 2 hot wires goign to the motor. I can't figure out any failafe for this.

In review, I obviously did the drawing wrong at the PS - Bottom left black and red lines should originate from a 12VDC PS, then divert up to relay and right to 12VDC to 5VDC converter module

Any ideas (other than scrapping the project which I am not willing to do)?

Last edited: