MrDEB

Well-Known Member

have built an URBAN CART. Can't call it a golf cart since it was not manfactured by a "golf cart company" as defined by state law.

Enough of usless jargen. I built a two seat cart for my wife that is powered by a 1400 watt 48 volt motor. I call it "hot rod golf cart".

yes it is street legal here in town 25mph speed limit.

Want to design a dash display with a 4x20 lcd that displays MPH, odometer,battery condition and outside temp. Just carry me away.

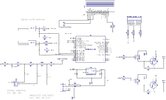

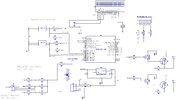

Using an 18f2221 pic , a temp sensor probe, a hall effect switch. Input the battery condition (48v Li-po4 battery) on a ADC input that is connected to a resistor ladder. see attached.

a 5v voltage regulator to power the pic

an RGB LED to visiulize battery condition (red= dead, green=good to go, blue=battery getting low)

An extra LED when exceeding 20mph. Easy to visiulize. could be a buzzer?

It has a backup buzzer already.

include a fuse array for lights, (brake, rear lights, headlights, motor )

the resistor array may need tsome adjustment since a 48v LIPO4 battery fully charged is 52-56volts.

any suggestions or additions?

Enough of usless jargen. I built a two seat cart for my wife that is powered by a 1400 watt 48 volt motor. I call it "hot rod golf cart".

yes it is street legal here in town 25mph speed limit.

Want to design a dash display with a 4x20 lcd that displays MPH, odometer,battery condition and outside temp. Just carry me away.

Using an 18f2221 pic , a temp sensor probe, a hall effect switch. Input the battery condition (48v Li-po4 battery) on a ADC input that is connected to a resistor ladder. see attached.

a 5v voltage regulator to power the pic

an RGB LED to visiulize battery condition (red= dead, green=good to go, blue=battery getting low)

An extra LED when exceeding 20mph. Easy to visiulize. could be a buzzer?

It has a backup buzzer already.

include a fuse array for lights, (brake, rear lights, headlights, motor )

the resistor array may need tsome adjustment since a 48v LIPO4 battery fully charged is 52-56volts.

any suggestions or additions?