hi Al.

This data is from LTSpice. I have attempted to normalise the thermistor and associated circuit to 25C.

If you look at the Table data and Plot from LTS you will see that the switching point

ie: Vref does change with temperature on the half bridge circuit.

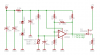

While it would in theory be possible to design the circuit as I half bridge using two matched NTC thermistors I would say in practice it would not be an option I would choose.

I would imagine trying to set up the hysteresis would be a task..

This data is from LTSpice. I have attempted to normalise the thermistor and associated circuit to 25C.

If you look at the Table data and Plot from LTS you will see that the switching point

ie: Vref does change with temperature on the half bridge circuit.

While it would in theory be possible to design the circuit as I half bridge using two matched NTC thermistors I would say in practice it would not be an option I would choose.

I would imagine trying to set up the hysteresis would be a task..