New to this forum and have a limited knowledge of electronics.

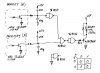

What I need is some help in the design of a circuit that will allow me to connect 2 identical proximity sensors (a) (b) in a way that when a metal object is detected by both sensor at the same time everything is OK. But if sensor (a) detects a metal object but sensor (b) does not I need to energize a relay.

The Proximity Sensors are 10-30V DC NPN Normally Open, 3 Wire, Switching Frequency 3kHz and are 4mm in diameter.

Relay would Have a 24V DC coil and a 5A contact rating. It will be used to light a warning Light and energize an air valve.

I am not sure how to do this and what I will need. I do know that the response time has to be quick. The metal objects will be traveling at about 800-1000 per minute and are less than 16th inch wide.

Any Ideas would be great

Thanks

What I need is some help in the design of a circuit that will allow me to connect 2 identical proximity sensors (a) (b) in a way that when a metal object is detected by both sensor at the same time everything is OK. But if sensor (a) detects a metal object but sensor (b) does not I need to energize a relay.

The Proximity Sensors are 10-30V DC NPN Normally Open, 3 Wire, Switching Frequency 3kHz and are 4mm in diameter.

Relay would Have a 24V DC coil and a 5A contact rating. It will be used to light a warning Light and energize an air valve.

I am not sure how to do this and what I will need. I do know that the response time has to be quick. The metal objects will be traveling at about 800-1000 per minute and are less than 16th inch wide.

Any Ideas would be great

Thanks