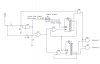

Hi There, I am curious if anyone would be able to help me in providing some circuit design ideas. I am a begginer with circuits and electronics and have created some circuits from online and book sources etc.. but not quite to the point of knowing enough to "design" my own. I need to make a circuit that controls a 6-12 volt DC gearmotor and it needs to do the following.

When a switch is flipped:

-Gearmotor turns on in one direction for 30 minutes.

-After 30 minutes the gear motor shuts off for 4 hours

-after 4 hours the motor turns back on again for 30 minutes but with the opposite polarity (direction)

-this process completes itself untill the switch is flipped to the off position.

Any help would be appreciated.

Thanks

When a switch is flipped:

-Gearmotor turns on in one direction for 30 minutes.

-After 30 minutes the gear motor shuts off for 4 hours

-after 4 hours the motor turns back on again for 30 minutes but with the opposite polarity (direction)

-this process completes itself untill the switch is flipped to the off position.

Any help would be appreciated.

Thanks