Sorry, yes, LM7812.

My problem is I'm an Mech Eng not an electronics wiz. I struggle.

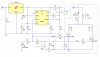

The circuit (Alec's post 42) seems fine & worked with a 9 v battery test run but seemed to fail when put it with 15 V power pack. I "thought" it safe to have the 1k ohms at the input in case 15 v would drive too much current. Well, it must be something else.

I have made a simple 555 astable (?got that right) at 20 Hz, and I use a Saleae Logic device with my Mac. I can no longer get an output signal on the Mac, nor the "light** flickering". I can't find a fault with the board so I blamed the 555. Luckily, I have just met a local Univ guy who can test it on a CRO, & apply a timed pulse.

Thanks for the reply. Its helpful.

Will report Monday.

** I have a Yellow LED and a 470 ohm R.