BGAmodz

Member

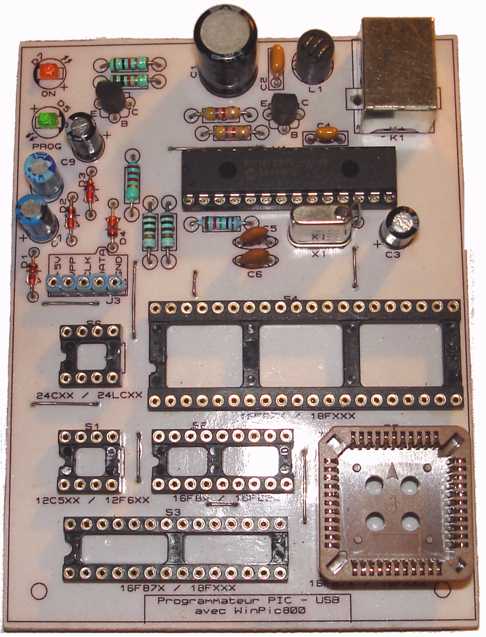

After choosing the right PIC USB programmer schematic i have decided to make a PCB with the help of traditional methods using :

Clothes iron

Ferrite chloride ( copper remover )

Copper surface.

Lazer printer .

Normal A4 paper .

Liquid soap .

Now according to the tutorial , i :

Printed the schematic on the paper ( Normal A4 paper ) , i have done that using lazer printer .

Let the clothes iron to heat up at max temp.

Put the paper on the copper surface

applied heat with pressure on the paper using the iron

After that i have directly put it in the liquid soap ( this is supposed to make the paper peel off easily from the copper surface ) and let it for about 4 minutes.

Now the problem is in the peeling process, i peel off the paper but there is a thin paper layer that is hard to remove , when i try to remove it with my hand the ink gets removed with it too .

Any ways i have continued the process , now i have to put the copper surface on the ferrite chloride to remove the copper and only the copper beneath the ink should stay .

After doing that i see the copper disappearing , i have left to to disappear entirely .

Now i only see the schematic lines alone witch is good , but the problem is that the ink is still hard to remove to let the copper lines appear ( probably because i did not remove all the paper in the previous step ?? )

I hope some one help me out on this .

Clothes iron

Ferrite chloride ( copper remover )

Copper surface.

Lazer printer .

Normal A4 paper .

Liquid soap .

Now according to the tutorial , i :

Printed the schematic on the paper ( Normal A4 paper ) , i have done that using lazer printer .

Let the clothes iron to heat up at max temp.

Put the paper on the copper surface

applied heat with pressure on the paper using the iron

After that i have directly put it in the liquid soap ( this is supposed to make the paper peel off easily from the copper surface ) and let it for about 4 minutes.

Now the problem is in the peeling process, i peel off the paper but there is a thin paper layer that is hard to remove , when i try to remove it with my hand the ink gets removed with it too .

Any ways i have continued the process , now i have to put the copper surface on the ferrite chloride to remove the copper and only the copper beneath the ink should stay .

After doing that i see the copper disappearing , i have left to to disappear entirely .

Now i only see the schematic lines alone witch is good , but the problem is that the ink is still hard to remove to let the copper lines appear ( probably because i did not remove all the paper in the previous step ?? )

I hope some one help me out on this .