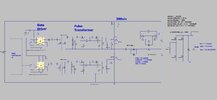

If i may please ask....We are doing a 2kW SMPS. PFC then Half Bridge LLC.

The main board has the chunky components on it and is rather large for this initial prototype (500mm x 400mm).

Therefore, we dare not put SMD on this potentially ‘bendy’ board. Though we need the Gate drive components to be SMD for sake of reducing stray L. As such, do you think the attached method is good for doing the gate drive with SMD daughter boards?

Its basically making the daughter board into a little kind of SMD component. (As SMD, The daughter board will be easier to remove if we need to, during testing.)

BTW, the cheap Chinese PCB Fabs don’t seem to be doing >1.6mm thickness on the cheap rates for our main board size, so we must use 1.6mm thick main board.

The below is the only thing I can find so far, but we need the legs to come “out” so we can solder them to the mains board SMD pads…..

https://uk.farnell.com/wurth-elektronik/61000418221/header-2-54mm-pin-smt-4way/dp/2356209

Is there such “SMD header” as in the attached picture? Basically we just want a header which will kind of put "legs" onto the daughter PCB.....to make it kind of like a SOIC8, type of thing...those kind of SMD "legs"

I mean, the below could kind of be hacked to do it..

https://uk.farnell.com/multicomp/mc34747/header-1-row-r-angle-3way/dp/1593427

....but its going to be a bit "raised" compared to a SOIC, kind of thing.

The main board has the chunky components on it and is rather large for this initial prototype (500mm x 400mm).

Therefore, we dare not put SMD on this potentially ‘bendy’ board. Though we need the Gate drive components to be SMD for sake of reducing stray L. As such, do you think the attached method is good for doing the gate drive with SMD daughter boards?

Its basically making the daughter board into a little kind of SMD component. (As SMD, The daughter board will be easier to remove if we need to, during testing.)

BTW, the cheap Chinese PCB Fabs don’t seem to be doing >1.6mm thickness on the cheap rates for our main board size, so we must use 1.6mm thick main board.

The below is the only thing I can find so far, but we need the legs to come “out” so we can solder them to the mains board SMD pads…..

https://uk.farnell.com/wurth-elektronik/61000418221/header-2-54mm-pin-smt-4way/dp/2356209

Is there such “SMD header” as in the attached picture? Basically we just want a header which will kind of put "legs" onto the daughter PCB.....to make it kind of like a SOIC8, type of thing...those kind of SMD "legs"

I mean, the below could kind of be hacked to do it..

https://uk.farnell.com/multicomp/mc34747/header-1-row-r-angle-3way/dp/1593427

....but its going to be a bit "raised" compared to a SOIC, kind of thing.

Attachments

Last edited: