ThomsCircuit

Well-Known Member

ive made the mistake before thinking what i have researched is and will do just what i want. Ive learned the hard way that's not always the case so Im going to ask for your opinions and perhaps use this as a starting point.

I have a workshop. Its full of wood chip throwing power tools. Some tools are connected to a vacuum (9amp) that ive designed to come on using just relays. This is because a master switch needs to be turned on to run the appliance so engaging the vacuum at the same time is a simple task. My chopsaw (9amp) however is slightly different where i pull a trigger on the appliance to turn it on so in order to have the vacuum power up after i pull the trigger i need a circuit that will sense the load draw from the chopsaw and trigger a relay that will then turn on the vacuum.

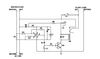

I have this circuit i found that trips a relay when a load is present. this circuit however is meant to turn on a monitor when the computer is turned on. It has a limit of 5 amps and there is no delay on or off of the "slave" device (vacuum)

the finished project will be enclosed on a box. It will be plugged into a 120V outlet for power. it will have a receptacle for the saw and a receptacle for the vacuum.

could you help me modify this to work with my 9amp chopsaw and vacuum? And I need the vacuum to wait 1 second before it starts and remain on after i release the trigger on the chopsaw for 3-5 seconds.

Im going to provide the schematic and the parts list for reference. I thank you in advance for your help.

I have a workshop. Its full of wood chip throwing power tools. Some tools are connected to a vacuum (9amp) that ive designed to come on using just relays. This is because a master switch needs to be turned on to run the appliance so engaging the vacuum at the same time is a simple task. My chopsaw (9amp) however is slightly different where i pull a trigger on the appliance to turn it on so in order to have the vacuum power up after i pull the trigger i need a circuit that will sense the load draw from the chopsaw and trigger a relay that will then turn on the vacuum.

I have this circuit i found that trips a relay when a load is present. this circuit however is meant to turn on a monitor when the computer is turned on. It has a limit of 5 amps and there is no delay on or off of the "slave" device (vacuum)

the finished project will be enclosed on a box. It will be plugged into a 120V outlet for power. it will have a receptacle for the saw and a receptacle for the vacuum.

could you help me modify this to work with my 9amp chopsaw and vacuum? And I need the vacuum to wait 1 second before it starts and remain on after i release the trigger on the chopsaw for 3-5 seconds.

Im going to provide the schematic and the parts list for reference. I thank you in advance for your help.