lorenzoarce

New Member

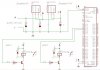

We have a board, which is powerd by an AC/DC converter of 12V and 2A. In the board there is a 5V regulator (LM1117-T-5.0) and another of 3.3V (LM1117-T-3.3). The 3.3V one is powered by the 5V one. The 3.3V regulator powers a MSP430F149 microcontroller. The 5V regulator powers the coils of 2 relays controlled by 2 relay drivers. These are made up of a transistor in cutoff/saturation which controlles the current throught the coil. Each driver is controlled by a digital output of the microcontroller.

The issue we have detected is that, sometimes, when we change the state of the drivers, the microcontroller resets. I guess it is a power problem, but I would appreciate any idea about what is happening there. I would thank you for any advise about what test I can do.

Thanks in advance. A simplified schematic is attached.

The issue we have detected is that, sometimes, when we change the state of the drivers, the microcontroller resets. I guess it is a power problem, but I would appreciate any idea about what is happening there. I would thank you for any advise about what test I can do.

Thanks in advance. A simplified schematic is attached.