If you've used micro's before, and have some PIC16F's about, then that's probably all you'll need

A scope is nice to sniff signals, but not always necessary - I doubt they'll be sending packets/bytes at 10MB/sec, so any logic analyzer will do, or even... the PICkit2's wonderful built in logic tool. Failing that, you could guess at the protocol used (I'm guessing opto-isolated UART-like structure..0-5V TTL) and either use your PC's serial port (USB to serial converter..) and terminal, or program a PIC that auto detects baud, and spits out that data in a known format to your PC's terminal. MikroC free version is often very easy to use for quick 'test' programs, as it has built in libraries. There are always many ways to do such things, just a question of time, money, and hassle.

A couple of links just in case you decide to go down this route (could be a bit of tangent from the actual project itself):

**broken link removed**

http://pe1grl.khds.nl/picla/picla.htm

I know what you mean about

determination and time over money - many of my hobby projects are based around this as.. anyone can throw £200 at something and make it work, but its always nice when you can delve into your 'bits box' and knock up something rather clever!

That velleman kit looks pretty cool, but I couldn't find any 'user friendly' ready-built windows apps to use with, seems it is mostly for people developing their own host software. In the modern world of open source, it is becoming harder to find just a very easy, simple 'exe' to run on windows, without having to recompile and jump through hoops.

If you don't want to fill the thread about the protocol, and keep it about hardware, then you can always pm me about PIC code.

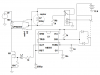

RonV has an excellent point. A simple circuit to pulse the up/down buttons. You could even use a micro for that - read in a pot, and when it changes send a pulse every time the ADC measurement changes by a certain amount. It only changes when you're turning the pot. Its a bit of a fudge, because no doubt the micro on board will debounce the buttons, limited how quickly you can pulse it to increment/decrement - as well as how quickly the motor speed changes. With the RPM readout on the LED display, that's your feedback