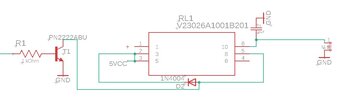

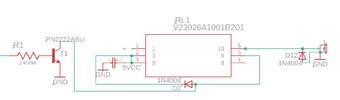

I have a simple design as shown below to drive a set of small self restoring solenoids. Using digital pins on Arduino Mega to toggle them off and on. I have a SN74AS1034AD digital buffer to interface the signals from Mega (pulled down using 10K at the digital buffer input pins) to Solenoid circuitry, while the power to the solenoid is controlled by a relay (RL1)

The issue is that sometimes, random solenoids get stuck in energized state. The voltage across the connector to solenoid stays 5V as soon as I power on the board. I checked the input from Mega, they are at 0V, the output of the buffer stays 0V, but the relay is being turned on which I am not able to understand.

thanks in advance

The issue is that sometimes, random solenoids get stuck in energized state. The voltage across the connector to solenoid stays 5V as soon as I power on the board. I checked the input from Mega, they are at 0V, the output of the buffer stays 0V, but the relay is being turned on which I am not able to understand.

thanks in advance