saiello

New Member

Hi All,

I posted a while back on the use of the PC parallel port to drive a DAC and ADC as an interface to a variety of sensors/PWM's. I breadboarded a circuit and have written the software in VB6. The DAC chip performed perfectly first time out ( not what I was expecting! ), I can specify a voltage by moving a slider in the software and instantly get a corresponding voltage output. The ADC uses the same SPI interface and is driven in a similar way to the DAC. Although I can get the ADC to respond and return a voltage, all I get back are random spurious readings even when trying to read the internal test reference voltage. I've been through the datasheet with a fine toothcomb but cannot find anything that could be causing the problem, at least from an electronics perspective. I've checked the software thoroughly, slowing the timings right down to tenths of a second, making sure that everything is synchronised in terms of input clock pulses and data and the converted output data, but it's got me stumped.

The ADC uses the same SPI interface and is driven in a similar way to the DAC. Although I can get the ADC to respond and return a voltage, all I get back are random spurious readings even when trying to read the internal test reference voltage. I've been through the datasheet with a fine toothcomb but cannot find anything that could be causing the problem, at least from an electronics perspective. I've checked the software thoroughly, slowing the timings right down to tenths of a second, making sure that everything is synchronised in terms of input clock pulses and data and the converted output data, but it's got me stumped.  If anyone has experience of the TLC2543 ADC or even of driving this IC through the parallel port I'd be greatful for any input!

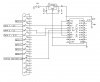

If anyone has experience of the TLC2543 ADC or even of driving this IC through the parallel port I'd be greatful for any input!  I've attached a schematic showing the breadboard setup.

I've attached a schematic showing the breadboard setup.

Thanks!

I posted a while back on the use of the PC parallel port to drive a DAC and ADC as an interface to a variety of sensors/PWM's. I breadboarded a circuit and have written the software in VB6. The DAC chip performed perfectly first time out ( not what I was expecting! ), I can specify a voltage by moving a slider in the software and instantly get a corresponding voltage output.

Thanks!