A while ago there was a thread that included a thermostat/heater for an incubator. I still do not know where the schematic came from, but I had the feeling that it was from a few years ago. I was thinking about it and wondered if I could do "better".

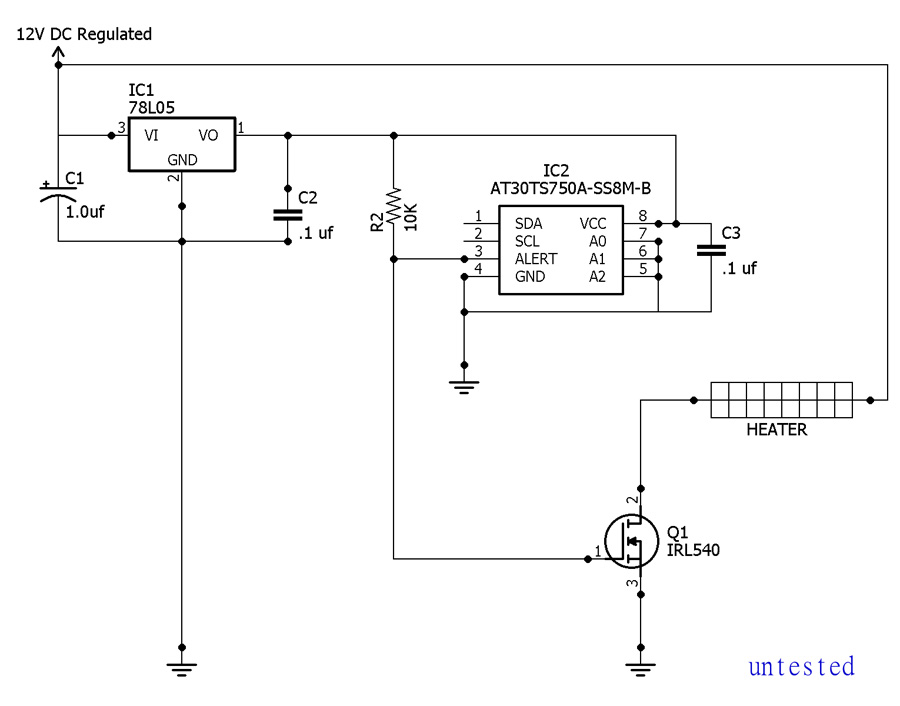

Here is what I have come up with so far:

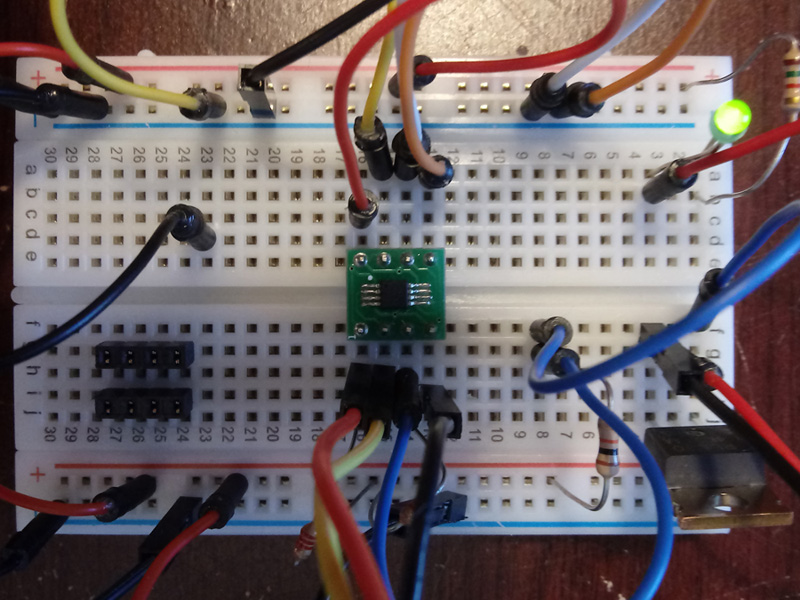

So far, I have only bread boarded it.

...and that is without the 78L05 and the IRL540 is only turning on an LED. The AT30TS750A is a pretty impressive chip...and at only US$1.30. Yes, you have to program it, but in this day and age...so what?

I also checked out the the older DS1626 and the max31723.

The only heater I have available is one of these (12V and measured at .75 AmA, although the IRL540 should be able to handle considerably more than that in this design).

I think that I will try to solder up a test version today.

Here is what I have come up with so far:

So far, I have only bread boarded it.

...and that is without the 78L05 and the IRL540 is only turning on an LED. The AT30TS750A is a pretty impressive chip...and at only US$1.30. Yes, you have to program it, but in this day and age...so what?

I also checked out the the older DS1626 and the max31723.

The only heater I have available is one of these (12V and measured at .75 A

I think that I will try to solder up a test version today.

Last edited: