As I've said repeatedly, if you use three AA NiMH batteries and a 200mA solar panel, you don't need to worry about limiting the voltage or the current.

All you need a diode to prevent the batteries from discharging back into the solar panel. I'd recommend a Schottky diode because the voltage drop is lower. If you're using a hand crank dynamo, you'll need to connect it via a separate diode, otherwise the lots of the power from the solar panel will go into powering the motor.

Hi there Hero,

I have to wonder, did you say what you really wanted to say there? You realize that

200ma for extended periods is enough to ruin the NiMH cells in a fairly short time like

3 months right? Are you perhaps basing this on the full sun shining only for short

periods per day?

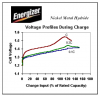

The charge regimen for charging NiMH cells incorporates either minus delta V, zero delta V,

max temperature cutout, (or a combination of those), and also a default timer.

I realize that the charge current is usually higher but 200ma is still enough.

For example, 90ma will kill the cells in about 6 months.

I guess at 200ma for 24 hours a day 7 days a week would not happen with a solar charger,

so figure 8 hours a day so that's about three times the life at 200ma, or 9 months. Not

too bad i guess.

Come to think of it, a solar source might require special thought as to how often to allow the

charger to actually charge. With the sun going down at night and then coming back up the

next day, the charger would probably go through the algorithm of minus delta V again, and

as each day passes it would go through this over and over again even if the cell hasnt been

drained each day. That might have a detrimental effect on the life of the cell too.