gubavac111

New Member

So, I've damaged 3 piezo buttons...

This is the piezo button: https://uk.rs-online.com/web/p/piezo-switches/1241087

Datasheet: https://docs.rs-online.com/9e69/0900766b8152fb83.pdf

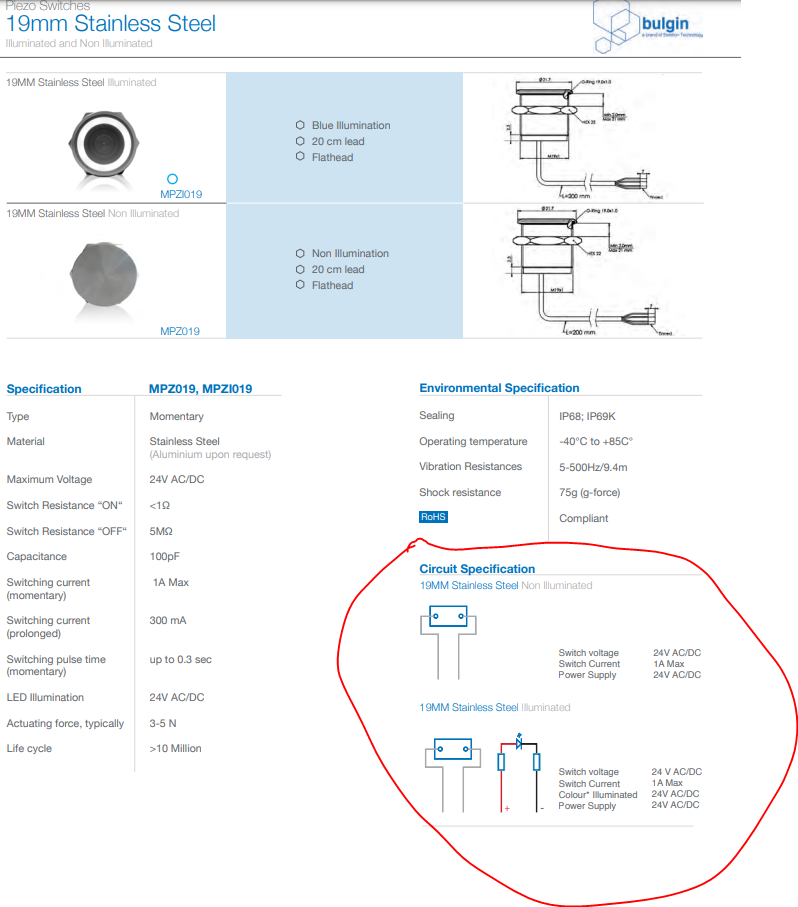

Quick explanation on what MPZI019/F/BL/24 is:

MPZI - Illuminated piezo switch

019 - 19mm diamater

F - Flat head

BL - color of illumination, in this case it is blue

24V - illuminating LED voltage

Also, it is a momentary switch, not latching.

This is the pinout:

This is how I connected it:

If you look at the datasheet, the switching contact is rated at 24VACDC 1 A.

It seems that I have destroyed 3 buttons.

There is a short between brown and yellow.

What did I do wrong???

This is the piezo button: https://uk.rs-online.com/web/p/piezo-switches/1241087

Datasheet: https://docs.rs-online.com/9e69/0900766b8152fb83.pdf

Quick explanation on what MPZI019/F/BL/24 is:

MPZI - Illuminated piezo switch

019 - 19mm diamater

F - Flat head

BL - color of illumination, in this case it is blue

24V - illuminating LED voltage

Also, it is a momentary switch, not latching.

This is the pinout:

This is how I connected it:

If you look at the datasheet, the switching contact is rated at 24VACDC 1 A.

It seems that I have destroyed 3 buttons.

There is a short between brown and yellow.

What did I do wrong???