I'm altering the fan ducts inside my car, so everything must be 12v.

I'd like to have a button that opens and closes a lid on a vent.

When the button is pushed, the vent opens, when the button is bushed again, the vent closes.

I'm thinking I could have a dc motor attached to the vent lid. Does anyone know a website that sells 12v motors w/ reverse? and what kind of a button am I looking for?

I'll have 12 buttons/vent lids, a button for each vent lid.

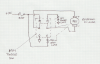

attached is a picture of what I'm talking about with the vent.

Thanks for the help! feel free to ask about something if I wasn't clear.

I'd like to have a button that opens and closes a lid on a vent.

When the button is pushed, the vent opens, when the button is bushed again, the vent closes.

I'm thinking I could have a dc motor attached to the vent lid. Does anyone know a website that sells 12v motors w/ reverse? and what kind of a button am I looking for?

I'll have 12 buttons/vent lids, a button for each vent lid.

attached is a picture of what I'm talking about with the vent.

Thanks for the help! feel free to ask about something if I wasn't clear.