heri

New Member

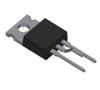

Hello you guys, thank you for accepting me here, right now I'm making a tool to dry the plastic filament, the unfinished part is the dimmer with a triac because MT 1 and MT 2 are on fire, like this has happened for the third time, then the input section exploded three times that caused the electricity at my house went out.

But this circuit works if I use breadboard but not veroboard, and this dimmer I combine with 555 timer IC (circuit diagram in figure 3 and figure 4b, https://www.nutsvolts.com/magazine/article/using-the-555-timer-ic-in-special-or-unusual-circuits). I do not know what caused it, hope you guys help me, thanks.

But this circuit works if I use breadboard but not veroboard, and this dimmer I combine with 555 timer IC (circuit diagram in figure 3 and figure 4b, https://www.nutsvolts.com/magazine/article/using-the-555-timer-ic-in-special-or-unusual-circuits). I do not know what caused it, hope you guys help me, thanks.