I am posting a thread similar to an old thread that Crutschow chimed in on with good advice; our application, however, *slightly* differs from the OP.

We ran into a similar "spark" issue when we energized, via a standard 120VAC wall outlet (service line at building) an AC/DC power supply /bridge rectifier that is installed on a piece of trailered equipment for off-grid use. We noticed that the trailer equipment assemblers jumpered N and G within the box on the trailer, so basically another jumper downstream of the neutral-to-earth bond at the breaker at our building.

We are going a bit back and forth about what to do. Here are some of the known facts:

- When we remove the jumper from N and G in the trailer equipment box that is downstream of the breaker box in the building, but upstream of the AC input to the bridge rectified power supply, we do not have issues with the power supply performance, or any sparking.

- When the jumper is used, it sparks.

- We use similar AC/DC power supplies on other equipment, where G from the AC input and V- from the isolated DC output are chassis grounded. I have not had issues with these, presumably because I do not jumper N and G.

My questions are:

What is the right approach here? Do we continue to not jumper N and G? As far as I understand (and I say that loosely) NEC prohibits secondary neutral-to-earth bonds anywhere other than the service panel / origin except in special circumstances with secondary equipment.

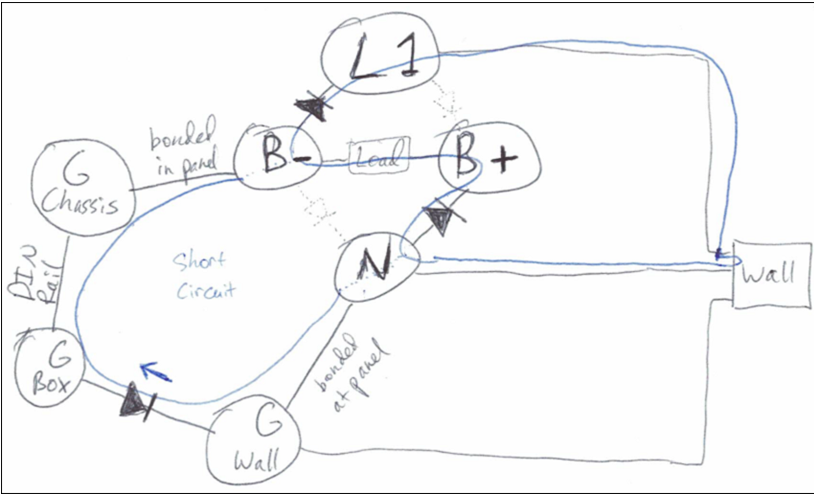

Or do we jumper N and G (seemingly a needless echo that they are ultimately jumpered somewhere else) and just place a diode between the chassis ground of the trailer and the ground of the wall outlet? (See pic) I have never seen this approach done on any oil&gas / industrial installation I've worked on.

Thanks

We ran into a similar "spark" issue when we energized, via a standard 120VAC wall outlet (service line at building) an AC/DC power supply /bridge rectifier that is installed on a piece of trailered equipment for off-grid use. We noticed that the trailer equipment assemblers jumpered N and G within the box on the trailer, so basically another jumper downstream of the neutral-to-earth bond at the breaker at our building.

We are going a bit back and forth about what to do. Here are some of the known facts:

- When we remove the jumper from N and G in the trailer equipment box that is downstream of the breaker box in the building, but upstream of the AC input to the bridge rectified power supply, we do not have issues with the power supply performance, or any sparking.

- When the jumper is used, it sparks.

- We use similar AC/DC power supplies on other equipment, where G from the AC input and V- from the isolated DC output are chassis grounded. I have not had issues with these, presumably because I do not jumper N and G.

My questions are:

What is the right approach here? Do we continue to not jumper N and G? As far as I understand (and I say that loosely) NEC prohibits secondary neutral-to-earth bonds anywhere other than the service panel / origin except in special circumstances with secondary equipment.

Or do we jumper N and G (seemingly a needless echo that they are ultimately jumpered somewhere else) and just place a diode between the chassis ground of the trailer and the ground of the wall outlet? (See pic) I have never seen this approach done on any oil&gas / industrial installation I've worked on.

Thanks