Hi guys,

I am trying to make a bluetooth audio module (based on CSR8645) run on a power supply. It has an input for +5V and draws about 60mA. Running it like this from a 7805 regulator produces a fair amount of high frequency switching type noise on the output though.

The module also has a connection for a 3.7V li-po battery so it can be used in portable devices. If I connect a battery on here, at the same time as the main power supply, the noise reduces significantly.

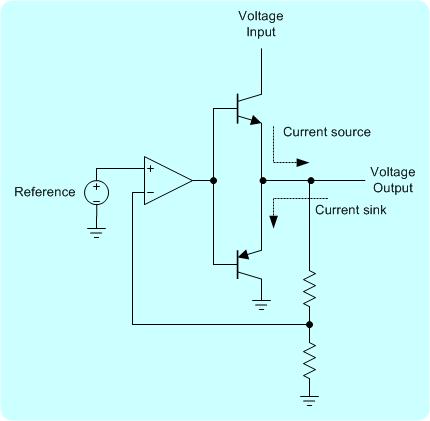

I guess the integrated battery charger circuit on the bluetooth device is 'looking' for a battery and putting out noise unless I connect one. My thought is that perhaps I need to build a regulator that can sink as well as source current and connect that in place of the battery. What do you think?

Can I just use a LM336Z5 (Fairchild) sunt reference with an adjust resistor to get a 3.7V output that can also sink current like a battery?

Thanks!

I am trying to make a bluetooth audio module (based on CSR8645) run on a power supply. It has an input for +5V and draws about 60mA. Running it like this from a 7805 regulator produces a fair amount of high frequency switching type noise on the output though.

The module also has a connection for a 3.7V li-po battery so it can be used in portable devices. If I connect a battery on here, at the same time as the main power supply, the noise reduces significantly.

I guess the integrated battery charger circuit on the bluetooth device is 'looking' for a battery and putting out noise unless I connect one. My thought is that perhaps I need to build a regulator that can sink as well as source current and connect that in place of the battery. What do you think?

Can I just use a LM336Z5 (Fairchild) sunt reference with an adjust resistor to get a 3.7V output that can also sink current like a battery?

Thanks!

Last edited: