HI, I learned alot about "efficiency" from projects similar to yours, as someone who shares a common interest in this regard i will tell you same as them: save your money.

If you would like to learn about the whys, then its best to read up on things like efficiency(energy in vs energy out), power output, power over time, resistance, work, force, and power losses. even if you have 100% efficient device you will still loose all power when you add a load(ie spin tires on road or add a lightbulb to electrical), similar to a dynamo

if you want to turbo your car use nitrous , if you are saving money get a smaller cylinder engine.

if you really want to test this get a solar cell and some LED's, hook it up in a pitch black room(ie.. no additional input power from lights), bring a flashlight so you can kick start it , but results are always same. also adding a battery(or capacitor) is just a buffer and only delays the inevitable failure.

or if you want to test your motor/gen config, don't bother with inefficient circuits and junk, such as 12v batteries, if your device is even 99% efficient and low resistance in mechanisms the motor/gen will continue to spin several cycles while slowly slowing to a stop.

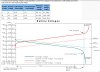

another test you can do is hook the motor to battery , and measure the Volts AND current used to power it(under load),, at the same time measure the volts AND current at the output of alternator:

Pout < Pin always

Power=Volts * Current

Pin - Pout = how fast it will slow down

Again, If you are truly interested in learning some of these things im sure we can help, but i think moderators ban overunity conversations due to the fact that most people that do this are just trying to save/make a buck and in the end are not interested in learning why it is not feasible or anything else, which in turn is a waste of our time trying to explain. since there is so much to know.

you will notice that you find alot of these people on youtube, but for some reason no one has marketable products. (I wish i could blame the govt for that, but alas,)

OVERALL, your switch is not needed , cos it will never be used, cos it will never turn off, cos a battery running a alternator to charge itself will never get anywhere without external energy being added(ie the flashlight),,, ie your design is literally wasting energy trying to save energy.

hopes helps!