Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Thanks Les,Hi spec,

I like the design of your toggle circuit with the latching relay. I don't see any problem the OP could find with this circuit as he has done with all the other suggestions.

Les.

Limit switches would be advisable in practice though, and over-current sensing might also be needed, as sooner or later the mechanism is likely to be jammed by chicken crapLimit switches could be incorporated but I though it better to keep the circuit as simple as possible.

NO power used when between operations and positive stop design with little opportunity for "drift". One "limit" switch. No power reversals.The problem with that is that I do not want the system to consume *any* power when it is offline

Hmm a new aspect, but I don't think that there is a time limit for the latching relay that Tony Stewart specified in post #92If you intend using latching relays, be aware that their coils can't be powered for lengthy periods. Here's an extract from a Shrack datasheet :

View attachment 100588

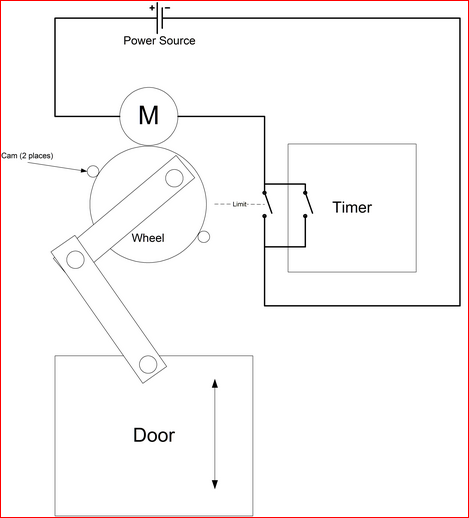

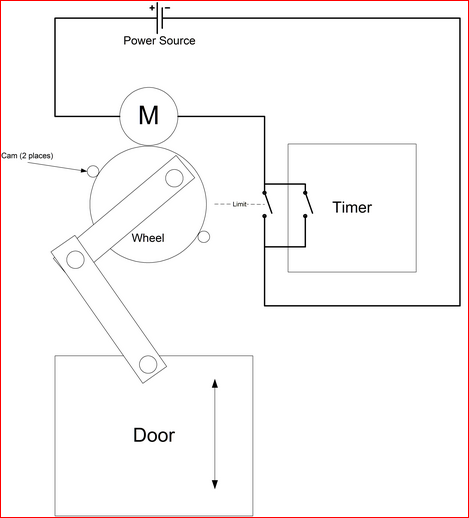

Once again, this design:

could not be more simple and it appears to meet the OP's basic concept, notably:

NO power used when between operations and positive stop design with little opportunity for "drift". One "limit" switch. No power reversals.

Now, decidedly not an elegant electronic solution and it would require some mechanical construction and alignment, but having followed this thread from post #1, there sure has been some impressive ink generated...

I like the simplicity, but I may not be able to adjust the motor components appropriately. I'll be looking into it.Brilliant cowboybob.

spec

Once again, this design:

could not be more simple and it appears to meet the OP's basic concept, notably:

NO power used when between operations and positive stop design with little opportunity for "drift". One "limit" switch. No power reversals.

Now, decidedly not an elegant electronic solution and it would require some mechanical construction and alignment, but having followed this thread from post #1, there sure has been some impressive ink generated...

I'd need a few tips before I could draw one that makes sense..If you post the schematic of your idea we should be able to tell if it will work.

Les.

cowboybob - I can't really tell how the limit switch is activated? In addition (and perhaps more importantly) one of the downsides of my motor is that it lifts by a string on a reel, so unless I take it apart and assemble complex gears (which I cant) then I need the system to be the standard forward/reverse model. Thanks for the design though! I'll have to keep the cam setup in mind for future projects as it is very elegant mechanically!