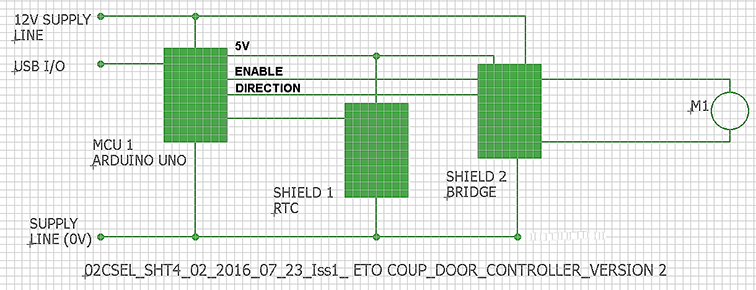

Here is an MCU version of the coop door controller:

Issue 33 of 2016_07_23

ERRATA

ERRATA

(1) 'COUP' should read 'COOP' in all instances

NOTES

(1) This is an outline functional block diagram of an Arduino Uno microprocessor unit (MCU) based coop door controller, as previously mentioned.

(2) This is an absolute system where the door opening and closing commands are absolute and not sequential

(3) The two shields (input output modules) just plug into the Arduino board and the two motor wires just fit into a terminal block on the bridge shield. No soldering is required.

(4) Including post and packing, the total cost is, £5.29UK:

(4.1) Arduino MCU: £3.00UK. **broken link removed**

(4.2) Real time clock (RTC) shield: £0.99UK**broken link removed**

(4.3) Motor driver twin bridge shield (L298 chip): £1.30UK. **broken link removed**

(5) Writing a sketch (program) to execute this task would be straightforward and simple.

(6) The Arduino sketch is written on a PC using the free Arduino Integrated Development Environment (IDE) and 'Processing' language. Python, C, or C++ languages could also be used.

(7) Door opening and closing times would be set with a PC or mobile phone (with appropriate application).

(8) Coup door opening and closing times can be set to any reasonable complexity, including automatically accounting for varying daylight time.

(9) Communication between the Arduino and PC/mobile phone for sketch loading and time setting is via a USB cable.

(10) Motor power dissipation can be limited by software timing if necessary and, in the extreme, the ST L298 chip on the bridge shield has motor current monitoring. https://www.st.com/content/st_com/en/products/motor-drivers/brushed-dc-motor-drivers/l298.html

(11) Apart from the motor, there are no moving parts to wear out.

(12) The RTC is battery backed so that the loss of 12V power will not corrupt the time.

(13) As the system is absolute, the temporary loss of 12V or door movement prevention, for any reason, will not put the door opening and closing sequence out of kilter.

(14) Note that the bridge shield already has four catching diodes incorporated for each of the two bridges (one bridge not used).

Issue 33 of 2016_07_23

(1) 'COUP' should read 'COOP' in all instances

NOTES

(1) This is an outline functional block diagram of an Arduino Uno microprocessor unit (MCU) based coop door controller, as previously mentioned.

(2) This is an absolute system where the door opening and closing commands are absolute and not sequential

(3) The two shields (input output modules) just plug into the Arduino board and the two motor wires just fit into a terminal block on the bridge shield. No soldering is required.

(4) Including post and packing, the total cost is, £5.29UK:

(4.1) Arduino MCU: £3.00UK. **broken link removed**

(4.2) Real time clock (RTC) shield: £0.99UK**broken link removed**

(4.3) Motor driver twin bridge shield (L298 chip): £1.30UK. **broken link removed**

(5) Writing a sketch (program) to execute this task would be straightforward and simple.

(6) The Arduino sketch is written on a PC using the free Arduino Integrated Development Environment (IDE) and 'Processing' language. Python, C, or C++ languages could also be used.

(7) Door opening and closing times would be set with a PC or mobile phone (with appropriate application).

(8) Coup door opening and closing times can be set to any reasonable complexity, including automatically accounting for varying daylight time.

(9) Communication between the Arduino and PC/mobile phone for sketch loading and time setting is via a USB cable.

(10) Motor power dissipation can be limited by software timing if necessary and, in the extreme, the ST L298 chip on the bridge shield has motor current monitoring. https://www.st.com/content/st_com/en/products/motor-drivers/brushed-dc-motor-drivers/l298.html

(11) Apart from the motor, there are no moving parts to wear out.

(12) The RTC is battery backed so that the loss of 12V power will not corrupt the time.

(13) As the system is absolute, the temporary loss of 12V or door movement prevention, for any reason, will not put the door opening and closing sequence out of kilter.

(14) Note that the bridge shield already has four catching diodes incorporated for each of the two bridges (one bridge not used).

Last edited: