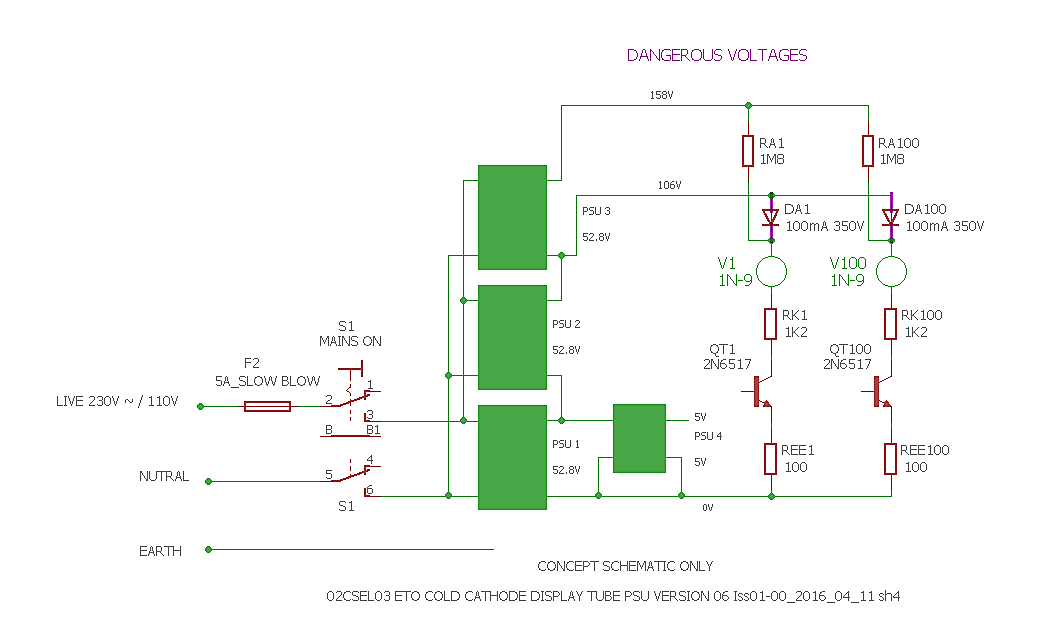

Here is another approach for the CC tube PSU which takes care of all the tolereancing problems by using stabilized supply rails. It embodies the principle of the Les buck strike supply (LBSS) to conserve power. It is also reasonably low power and low cost and requires no circuit building. With the specified PSUs, 416 tubes could be supported.

DATA SHEETS & SOURCES

(1) PSU 1 to 3

**broken link removed**

**broken link removed**

(2) PSU 4 (mains powered)

**broken link removed**

NOTES

(1) For this design it is fundamental that PSU 1 to 3 are isolated types.

(2) PSU 1 to 3 are 48V types that can be adjusted by +- 10 %. The approach above uses the PSUs adjusted to their maximum of 52.8V

(3) It may be possible to locate smaller units for PSU 1 to 3

(4) PSU 1 to 3 will operate from 100V and 230V with no change of the tube supply rails while still maintaining essentially the same efficiency.

(4) PSU 4 is a simple low cost, non isolated, 52.8V to 5V board-level buck switch mode PSU for the control electronics, about £2 on Ébay. On reflection, it would probably be better to use a separate mains powered PSU to generate the 5V for the control electronics.

(5) DA1 to DA100 should be low leakage types. Their forward drop is not important, within reason. They do not need to withstand high surge currents as in the case for rectifier diodes.

(6) The worst case power dissipation of the transistors is only 250mW.

(7) The worst case power dissipation of the resistors is also 250mW

ERRATA

(1) For every 5 tubes fitted, place 1 high frequency decoupling capacitor between the 106V supply line and 0V.

(2) For every 10 tubes fitted, place 1 high frequency decoupling capacitor between the 158V supply line and 0V.

(1) PSU 1 to 3

**broken link removed**

**broken link removed**

(2) PSU 4 (mains powered)

**broken link removed**

NOTES

(1) For this design it is fundamental that PSU 1 to 3 are isolated types.

(2) PSU 1 to 3 are 48V types that can be adjusted by +- 10 %. The approach above uses the PSUs adjusted to their maximum of 52.8V

(3) It may be possible to locate smaller units for PSU 1 to 3

(4) PSU 1 to 3 will operate from 100V and 230V with no change of the tube supply rails while still maintaining essentially the same efficiency.

(4) PSU 4 is a simple low cost, non isolated, 52.8V to 5V board-level buck switch mode PSU for the control electronics, about £2 on Ébay. On reflection, it would probably be better to use a separate mains powered PSU to generate the 5V for the control electronics.

(5) DA1 to DA100 should be low leakage types. Their forward drop is not important, within reason. They do not need to withstand high surge currents as in the case for rectifier diodes.

(6) The worst case power dissipation of the transistors is only 250mW.

(7) The worst case power dissipation of the resistors is also 250mW

ERRATA

(1) For every 5 tubes fitted, place 1 high frequency decoupling capacitor between the 106V supply line and 0V.

(2) For every 10 tubes fitted, place 1 high frequency decoupling capacitor between the 158V supply line and 0V.

Last edited: