Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I'm glad you're not offended.be80be said:hero999 you anit hurt my feeling the board had the holes in it when I found it.

It came off a motor controller and i sanded off where four wires was solder to it and reused it just to try it out never did it before the one hole on the right hit where two

resistors went and the jumper I forgot to run the ground to the header I like junk have a basement full of it. and plan to use it some where. LOL

Hello Mr RB,

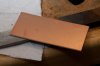

Frank here from Pulsar. The sharpness of transferred images is directly related to exceeding one of 4 parameters that must be controlled (eg. Time, Heat, Pressure & Toner Density). We want maximum pressure as a constant then with enough heat, we effect the toner's "sticky" state and don't encroach on the "melting" temp! Partial melting is what makes traces distort. This is why the "laminator" works so well at making perfect transfers every time. We have a short procedure on the website to "calibrate" an iron. It's the trick that makes the iron work as well as the laminator approach, albeit a bit more work.

Frank

Another thing: I strongly recommend removing the flux with an alcohol based solvent after soldering, otherwise it can cause corrosion problems.

Another thing: I strongly recommend removing the flux with an alcohol based solvent after soldering, otherwise it can cause corrosion problems.