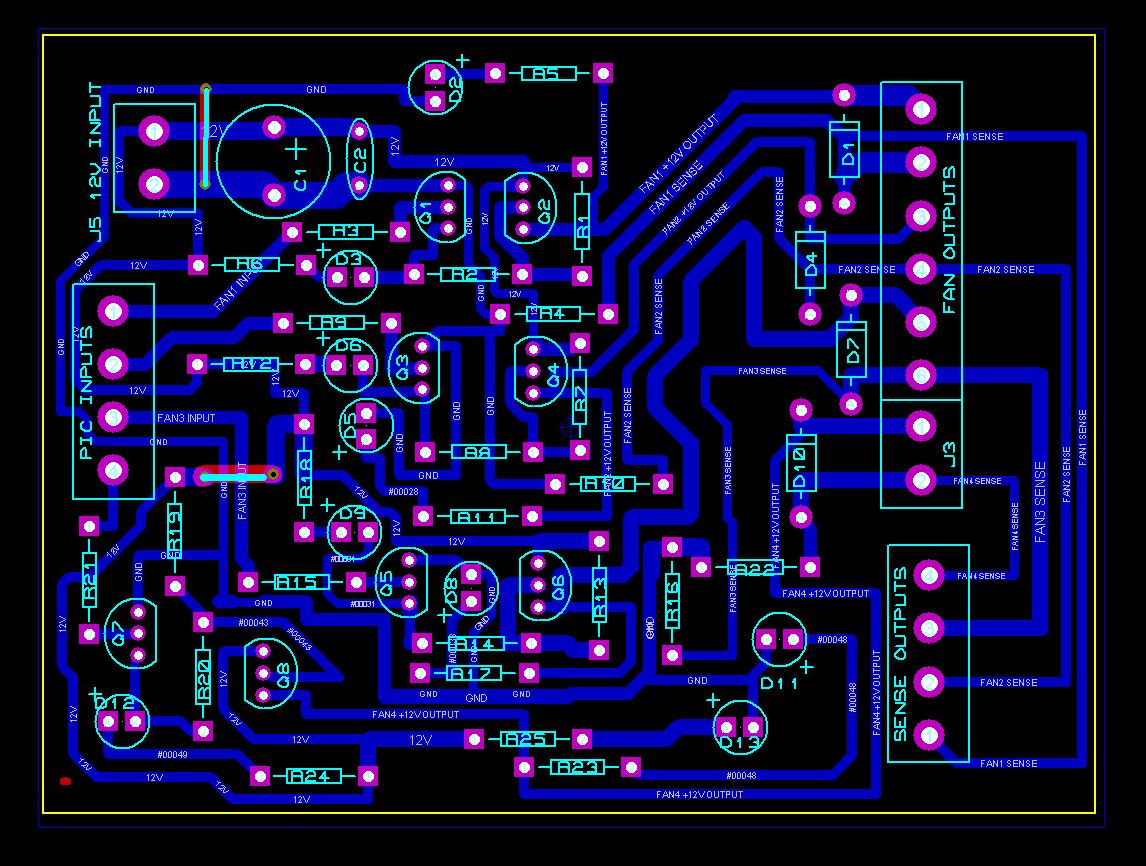

finished the layout but very not happy with it! loads of things i will change on the mark2. still it will do for now and i can replace later, but this one will get me in the race  also having trouble getting the pcb image on the pcb!!doing everything normal but not working!!! need to take calm approach later and try again!

also having trouble getting the pcb image on the pcb!!doing everything normal but not working!!! need to take calm approach later and try again!

forgot to mention as this one is so crap there is NO copy write on it lol

forgot to mention as this one is so crap there is NO copy write on it lol