I have a device (electronic level) with a control board/readout and a sensor board. They are connected with a 4-wire cable. I would like to use wireless communication between the two boards, but know close to nothing about serial communications. I have used Linx Technologies wireless Rx/Tx for encoded communications. I would like to avoid using a microcontroller just for simplicity sake.

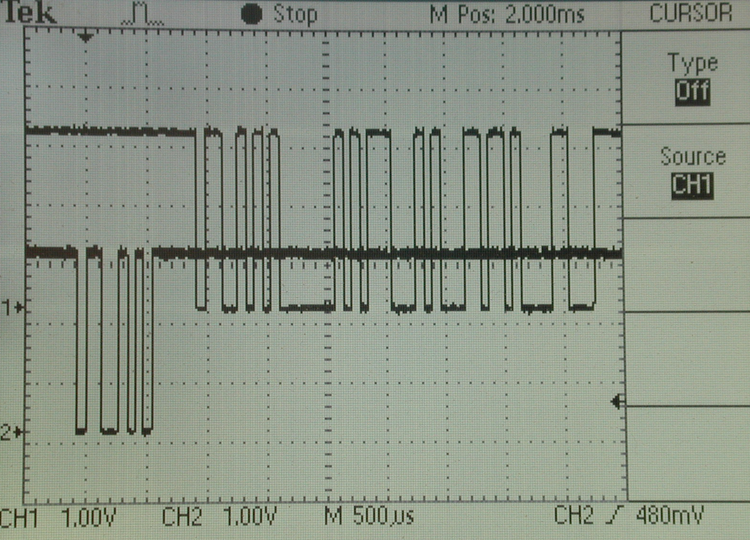

Here is a tracing of the communications between the controller and sensor:

The bottom trace is sent from the controller to the sensor. The sensor response is shown in the upper trace. With the various modules available, for example these: https://www.digi.com/products/wireless-wired-embedded-solutions/zigbee-rf-modules/

How does one control the timing and recognition of the request data? Can anyone suggest a good introductory manual wth maybe some examples?

Thanks,

John

Here is a tracing of the communications between the controller and sensor:

The bottom trace is sent from the controller to the sensor. The sensor response is shown in the upper trace. With the various modules available, for example these: https://www.digi.com/products/wireless-wired-embedded-solutions/zigbee-rf-modules/

How does one control the timing and recognition of the request data? Can anyone suggest a good introductory manual wth maybe some examples?

Thanks,

John

Attachments

Last edited: