Hi all.

I recently purchased a (obviously) second hand CRO oscilloscope.

It worked fine for a couple of days, I was just getting used to it.

Then one day, I left it on for 10 mins or so with both traces active on screen.

A while later, I heard this high frequency hiss, so I switched it off.

The traces were still active when I switched it off.

Now, when i switch it on, I get no traces whatsoever, although the power switch turns on, power light turns on.

After a minute or so, which is probably the standard warm up time before you'd normally see the traces, I can hear the hiss again.

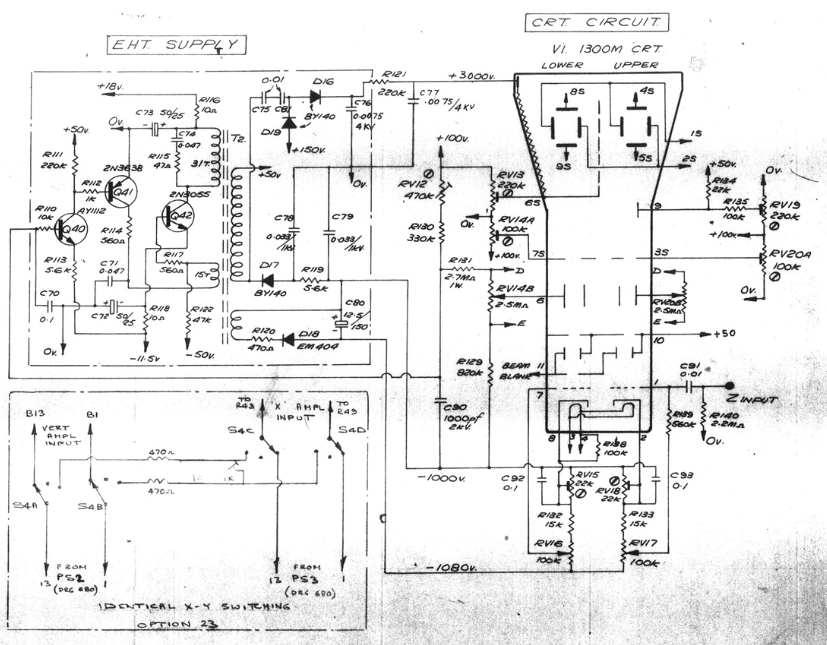

I removed the side cover, and the noise seems to be coming from the EHT supply board.

Checking further, there is a 2N3055 NPN power transistor that appears to be the source of the noise.

Furthermore, it quickly gets too hot to touch!

I've checked all the resistors on the EHT supply board, and all seem OK.

I've checked the voltages on the board, and many seem lower than expected.

I didn't have any equipment to test the 3000v, -1080 or -1000 lines, but here are the other voltages I measured.

reference | actual

-11.5 | -7.7

-50 | -44.5

18 | 16.5

50 | 47

165 | 85

Now, I realise many people may suggest just replacing it with another scope - and probably a digitial one, but for what I want to do with it, it has to be analog.

I can either try to repair this unit, or take another punt on buying another second hand CRO.

So, I'd like to try to fix it.

I suspect the 2N3055 is the culprit, but I am concerned its behaviour could be caused by a fault or short in the flyback transformer in the EHT supply, or possibly even the tube itself.

I haven't yet discharged the tube and cleaned the connection from the flyback transformer cable - I have read that sometimes in some CRT devices this fixes the hiss, but given the heat generated in the 2N3055 I'm thinking more likely a short in the transformer...

Does anyone have any suggestions of where to start, or any ideas that may help?

I did happen to get a brand new (30+ years old) tube as a spare with this unit, so if it is the tube, that's not such a problem.

The service manual for the unit is here:

https://elektrotanya.com/bwd_electronics_bwd-521_oscilloscope.pdf/download.html

The relevant part of the schematic from the manual I've attached.

If you require any further information, please let me know.

Thank you.

I recently purchased a (obviously) second hand CRO oscilloscope.

It worked fine for a couple of days, I was just getting used to it.

Then one day, I left it on for 10 mins or so with both traces active on screen.

A while later, I heard this high frequency hiss, so I switched it off.

The traces were still active when I switched it off.

Now, when i switch it on, I get no traces whatsoever, although the power switch turns on, power light turns on.

After a minute or so, which is probably the standard warm up time before you'd normally see the traces, I can hear the hiss again.

I removed the side cover, and the noise seems to be coming from the EHT supply board.

Checking further, there is a 2N3055 NPN power transistor that appears to be the source of the noise.

Furthermore, it quickly gets too hot to touch!

I've checked all the resistors on the EHT supply board, and all seem OK.

I've checked the voltages on the board, and many seem lower than expected.

I didn't have any equipment to test the 3000v, -1080 or -1000 lines, but here are the other voltages I measured.

reference | actual

-11.5 | -7.7

-50 | -44.5

18 | 16.5

50 | 47

165 | 85

Now, I realise many people may suggest just replacing it with another scope - and probably a digitial one, but for what I want to do with it, it has to be analog.

I can either try to repair this unit, or take another punt on buying another second hand CRO.

So, I'd like to try to fix it.

I suspect the 2N3055 is the culprit, but I am concerned its behaviour could be caused by a fault or short in the flyback transformer in the EHT supply, or possibly even the tube itself.

I haven't yet discharged the tube and cleaned the connection from the flyback transformer cable - I have read that sometimes in some CRT devices this fixes the hiss, but given the heat generated in the 2N3055 I'm thinking more likely a short in the transformer...

Does anyone have any suggestions of where to start, or any ideas that may help?

I did happen to get a brand new (30+ years old) tube as a spare with this unit, so if it is the tube, that's not such a problem.

The service manual for the unit is here:

https://elektrotanya.com/bwd_electronics_bwd-521_oscilloscope.pdf/download.html

The relevant part of the schematic from the manual I've attached.

If you require any further information, please let me know.

Thank you.