easy.rahil

Member

hello experts,

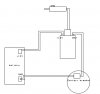

i m trying to make an electronic ignition like pamco and got similar design from a friend, i make homemade pcb for this schematic but output is coming without using magnet(added an led to check output and its constant on). can anyone guide me?

PCB

I m using MLX90217 geartooth sensor in place of A1250 Hall sensor.

U1 is IRGB14C40L mosfet.

Also let me know if there is any other hall sensor i can use

please let me know what is the actual problem

i m trying to make an electronic ignition like pamco and got similar design from a friend, i make homemade pcb for this schematic but output is coming without using magnet(added an led to check output and its constant on). can anyone guide me?

PCB

I m using MLX90217 geartooth sensor in place of A1250 Hall sensor.

U1 is IRGB14C40L mosfet.

Also let me know if there is any other hall sensor i can use

please let me know what is the actual problem