Hello everybody,

I have a project I have been working on it for a while and now it is the time for producing the pcb board...however, It is not so easy as writing....

I have some positive photoresist coated boards. I did not coat them with positv20 spray or smth similar.

before advancing to the original project, I cut some small pieces of pcb board and tired to find exposure and development times...

I find that, with the black light I have, 12min exposure is necessary. I used a NaOH solution for developing step and after almost 2min the patterns were nicely observable on the board.

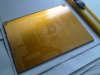

as the final step I etch the board with Fe3Cl solution. however, it does not go further even though I waited half an hour and put the container in a hot water bath. there are some areas close to the board edge where were partly etched and some spots on the board. put the pattern is not appearing.

the situation makes me quite curious because the main project is a double sided board...

So, I would like to hear your ideas.

I have a project I have been working on it for a while and now it is the time for producing the pcb board...however, It is not so easy as writing....

I have some positive photoresist coated boards. I did not coat them with positv20 spray or smth similar.

before advancing to the original project, I cut some small pieces of pcb board and tired to find exposure and development times...

I find that, with the black light I have, 12min exposure is necessary. I used a NaOH solution for developing step and after almost 2min the patterns were nicely observable on the board.

as the final step I etch the board with Fe3Cl solution. however, it does not go further even though I waited half an hour and put the container in a hot water bath. there are some areas close to the board edge where were partly etched and some spots on the board. put the pattern is not appearing.

the situation makes me quite curious because the main project is a double sided board...

So, I would like to hear your ideas.