Where I used to work, the technician would secure trimmer pots in position with a drop of nail polish. This kept the adjustment in position, yet still allowed it to be adjusted in the future.

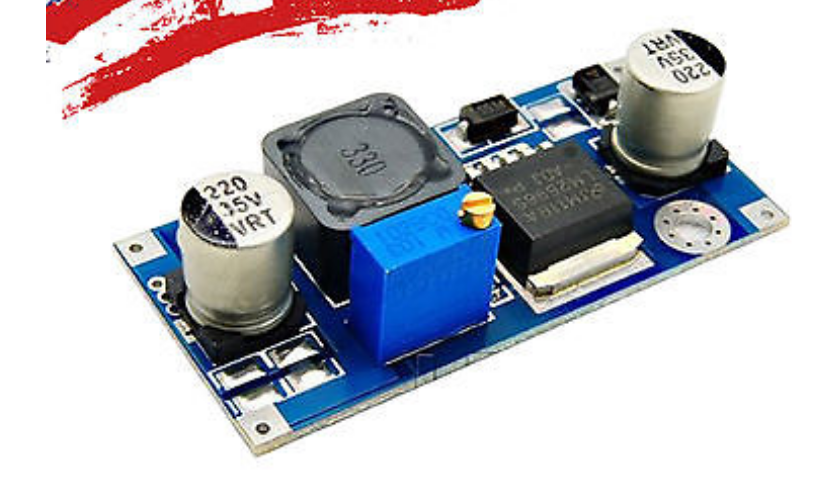

In high-vibration applications do you think this is necessary? I'm using DC-DC converters like the one pictured, and a change in voltage will either interfere with operation or damage the connected circuits.

Is there a better choice than nail polish for this? Acrylic paint would probably work as well. A nice dot of red nail polish is a quick way to see the pot has been adjusted!

The "7 transistor" radios of days past always had daps of what looked like red paint securing all the coils and other adjustable components.

In high-vibration applications do you think this is necessary? I'm using DC-DC converters like the one pictured, and a change in voltage will either interfere with operation or damage the connected circuits.

Is there a better choice than nail polish for this? Acrylic paint would probably work as well. A nice dot of red nail polish is a quick way to see the pot has been adjusted!

The "7 transistor" radios of days past always had daps of what looked like red paint securing all the coils and other adjustable components.