heri

New Member

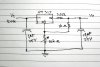

It's still part of the same project I've posted before but different parts, this is a turntable with a motor and voltage regulator. On YouTube they use synchronous motor, short story I bought stepper motor with driver in my local store, I intend to run this stepper motor like dc motor that I connect to voltage regulator to set the speed of rotation. Can it be done without driver and microcontroller?