StudentSA

Member

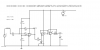

Lets do this design... for your case.... lets assume Fmax = 300Hz based on (4000 RPM * 4 (four cut flywheel?))/60sec = 264 Rounded up to 300.

Your Vcc is your supply! Not the internal zener regulated voltage. Remember the collector emitter of your output transistor is driven by the supply.

Now...

Fmax = I2/(C1*Vcc)

Thus C1 < 50nF

Now... R1 >= V3Max /I3min (from datasheet)

You want 0 -5 V?

So R1 >= 5/140uA >= 35714

Thus R1 >35714

Now we solve

Vout = Vcc x Fin x C1 x R1

5 = 12 x 265 x C1 x R1

5/(12*265) = R1 x C1

R1 = 5/(12*265*c1)

If we assume standard cap values below 50nf ... 47nF, 33nF, 22nF and 10nf

If C1 = 47nF .... R1 = 33453 Not Applicable as R1 is too small

If C1 = 33nF .... R1 = 47646 Great using a 47k resistor should be good enough

if C1 = 22nF .... R1 = 71469 Good 68k resistor plus 10k trim pot allow good accuracy

if C1 = 10nF .... R1 = 157232 maybe bit too high

So I advise trying C1 = 33nF or 22nF and the appropriate resistor

Best of luck mate

Your Vcc is your supply! Not the internal zener regulated voltage. Remember the collector emitter of your output transistor is driven by the supply.

Now...

Fmax = I2/(C1*Vcc)

Thus C1 < 50nF

Now... R1 >= V3Max /I3min (from datasheet)

You want 0 -5 V?

So R1 >= 5/140uA >= 35714

Thus R1 >35714

Now we solve

Vout = Vcc x Fin x C1 x R1

5 = 12 x 265 x C1 x R1

5/(12*265) = R1 x C1

R1 = 5/(12*265*c1)

If we assume standard cap values below 50nf ... 47nF, 33nF, 22nF and 10nf

If C1 = 47nF .... R1 = 33453 Not Applicable as R1 is too small

If C1 = 33nF .... R1 = 47646 Great using a 47k resistor should be good enough

if C1 = 22nF .... R1 = 71469 Good 68k resistor plus 10k trim pot allow good accuracy

if C1 = 10nF .... R1 = 157232 maybe bit too high

So I advise trying C1 = 33nF or 22nF and the appropriate resistor

Best of luck mate