I own a Fiat Punto 12+. This car can not be fooled with canbus LED lights, other than using a resistor. But then the car will never detect a defect bulb anymore, untill the resistor will be defect to. So I am planning to build a box with some components to fool the canbus, but also with a faulty LED "detector" in it. So the plan is as following:

Form the light switch of the car, the cable will run in to the box. It will run thru a relay (the switchable side), then a resistor is placed and then it is grounded to the chassis.

That way, when the relay is in closed position, the car thinks there is a working light, so no canbus light warning. Before the relay, the wire will be tapped and connected to the LED light and the LED light is also connected to the ground. Then the hard part: I want to have someting to have the relay switch to the open position, as soon as the LED light is faulty.

So what I first need to know is: can I measure a faulty LED bulb, in my case it will be a BAU15s 5w LED bulb and if yes, what difference in voltage/amps/resistance will I meausure when a LED is faulty and it what ways can a LED be faulty?

Visual experience of my own have seen LED bulbs that just won't lightup/went out and LED bulbs that are flickering.

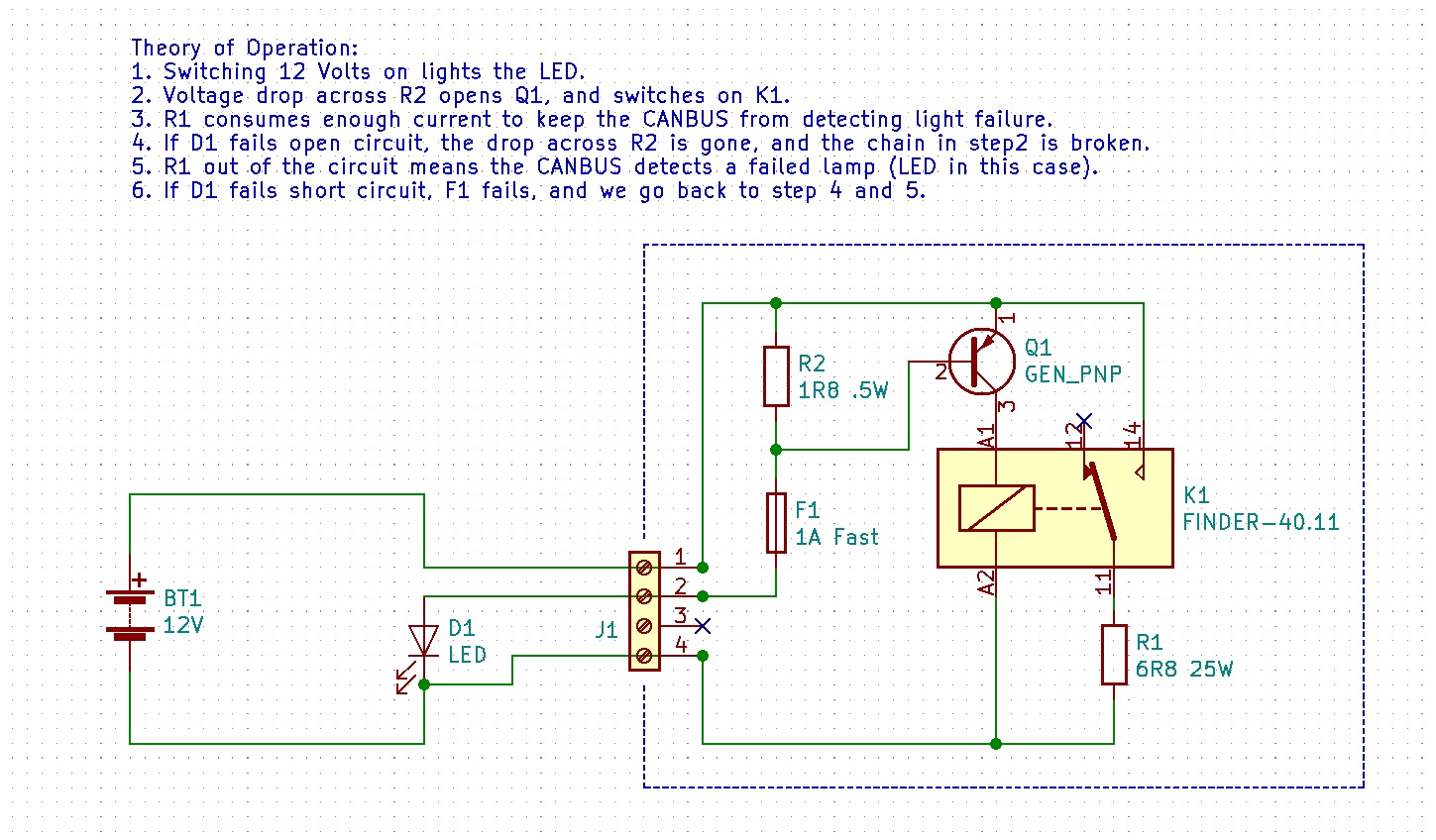

My father in law had the following idea:

BT1 will be the cars light switch.

Will this work, is there a better or other way to "open" the relay when the LED bulb is faulty or maybe a solution that will detect more faults?

I hope you can help me with this.

With kind regards,

Tinjo

Form the light switch of the car, the cable will run in to the box. It will run thru a relay (the switchable side), then a resistor is placed and then it is grounded to the chassis.

That way, when the relay is in closed position, the car thinks there is a working light, so no canbus light warning. Before the relay, the wire will be tapped and connected to the LED light and the LED light is also connected to the ground. Then the hard part: I want to have someting to have the relay switch to the open position, as soon as the LED light is faulty.

So what I first need to know is: can I measure a faulty LED bulb, in my case it will be a BAU15s 5w LED bulb and if yes, what difference in voltage/amps/resistance will I meausure when a LED is faulty and it what ways can a LED be faulty?

Visual experience of my own have seen LED bulbs that just won't lightup/went out and LED bulbs that are flickering.

My father in law had the following idea:

BT1 will be the cars light switch.

Will this work, is there a better or other way to "open" the relay when the LED bulb is faulty or maybe a solution that will detect more faults?

I hope you can help me with this.

With kind regards,

Tinjo