stevenh

Member

To everyone, from a fairly uneducated newbie

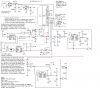

I've just recently completed a DCC (Model Railway Command Control) Booster Circuit of which I can successfully control my DCC-equipped trains from my com port. A schematic of the circuit is here: [See attachment: 941202_s.gif]

I've realised one huge issue though... if the tracks happen to short then things start either cooking or exploding; which, as you could imagine, is not the result I'm after...

I'd read the information on page 3 of this document [See Attachment: 1681.pdf]

and attempted to apply it between '1EN' and the L298 but to no avail...

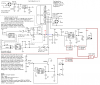

I then saw a similar circuit here: [See Attachment: bstr-1.gif]

that ties the 'current sense' pin to ground with a huge 0.47/5Watt resistor but also feeds it back into a TL072 to disable the input (although it doesn't seem to control the actual '1EN' pin?)

Due to a lack of knowledge though, I have no idea how to combine this into the current schematic as the 'current sense' pin is already tied to the feedback circuit and the '1EN' is tied into the 555 timer to only enable the output on data input...

I imagine I need a way of combining the 555 input into an AND gate of some form? Or something similar to only enable when the current sense is minimal? 3-4A would be a good current rating... but anything above 1A is great.

I'm currently using a ~13.8v DC transformer to power the circuit.

Any help would be greatly appreciated

(Apologies for attaching everything... I couldn't post links as it's my first post?)

Thanks, Steven.

I've just recently completed a DCC (Model Railway Command Control) Booster Circuit of which I can successfully control my DCC-equipped trains from my com port. A schematic of the circuit is here: [See attachment: 941202_s.gif]

I've realised one huge issue though... if the tracks happen to short then things start either cooking or exploding; which, as you could imagine, is not the result I'm after...

I'd read the information on page 3 of this document [See Attachment: 1681.pdf]

and attempted to apply it between '1EN' and the L298 but to no avail...

I then saw a similar circuit here: [See Attachment: bstr-1.gif]

that ties the 'current sense' pin to ground with a huge 0.47/5Watt resistor but also feeds it back into a TL072 to disable the input (although it doesn't seem to control the actual '1EN' pin?)

Due to a lack of knowledge though, I have no idea how to combine this into the current schematic as the 'current sense' pin is already tied to the feedback circuit and the '1EN' is tied into the 555 timer to only enable the output on data input...

I imagine I need a way of combining the 555 input into an AND gate of some form? Or something similar to only enable when the current sense is minimal? 3-4A would be a good current rating... but anything above 1A is great.

I'm currently using a ~13.8v DC transformer to power the circuit.

Any help would be greatly appreciated

(Apologies for attaching everything... I couldn't post links as it's my first post?)

Thanks, Steven.

Attachments

Last edited: