Krumlink

New Member

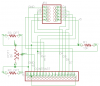

Well right now as far as electronics goes, I have been working on a little 18F4620 control board, and I have figured out what ports will do what:

PORTA Motor Control, LED output for Motor controls

PORTB Sensor Interaction/LED indicators

PORTC Sensor Interface?

PORTD Dunno?

PORTE Use E0,E1 E2 (E3 is reset, want to have that seprate) as LED indicators

Problem is, that I have a lot of pins and ports to work with (take that Basic s*** 2)

So I was wondering what should I do with Port C and Port D? I was thinking of using them and bringing the pins to a LCD board (I understand the basics of LCD's now ) and I am thinking that would be a good idea.

) and I am thinking that would be a good idea.

I have each port brought out to 2x5 headers (awesome idea by 3v0 on his boards) and I could easily change the function if needed. I have a HD74480 LCD so I can easily communicate with it, and I have already programmed a LCD with my uPICFAT to display "WHAT CHU TALKIN BOUT WILLIS" on it. I have also just started with INPUT commands too, and by taking data from an input and displaying it on the LCD (button input).

So what should I do with entire PORTC and PORTD?

www.crosstheroadelectronics.com for the uPICFAT (I got mine for free, the guy who sells them is a mentor on team 217 Thunderchickens who is visiting my HS today )

)

PORTA Motor Control, LED output for Motor controls

PORTB Sensor Interaction/LED indicators

PORTC Sensor Interface?

PORTD Dunno?

PORTE Use E0,E1 E2 (E3 is reset, want to have that seprate) as LED indicators

Problem is, that I have a lot of pins and ports to work with (take that Basic s*** 2)

So I was wondering what should I do with Port C and Port D? I was thinking of using them and bringing the pins to a LCD board (I understand the basics of LCD's now

I have each port brought out to 2x5 headers (awesome idea by 3v0 on his boards) and I could easily change the function if needed. I have a HD74480 LCD so I can easily communicate with it, and I have already programmed a LCD with my uPICFAT to display "WHAT CHU TALKIN BOUT WILLIS" on it. I have also just started with INPUT commands too, and by taking data from an input and displaying it on the LCD (button input).

So what should I do with entire PORTC and PORTD?

www.crosstheroadelectronics.com for the uPICFAT (I got mine for free, the guy who sells them is a mentor on team 217 Thunderchickens who is visiting my HS today