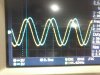

Hmm.. yeah. You can't use the negative values in the PWM module to set duty cycle.. it does not work properly.

I would still use negative numbers int the LUT though, because that is more natural presentation of sine signal (it oscillates around zero).

I would still use negative numbers int the LUT though, because that is more natural presentation of sine signal (it oscillates around zero).