Hi,

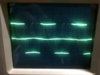

It's been a long long time since i worked with three phase synth sine wave converters, but it seems that if we designed a half bridge that puts out a synth sine with a fictitious ground at 1/2 Vcc, we'd have one phase done. The next phase would be the same exact thing except the pattern offset by 120 degrees, and the next phase by another 120 degrees. But then the peaks would be limited to 1/2 Vcc rather than Vcc which we get with a single phase H bridge. So maybe we'd want to think about creating the pattern distinct from the single phase approach, unless maybe we're using an output transformer.

Not sure how you guys are approaching this here though. Maybe you can enlighten me.

It's been a long long time since i worked with three phase synth sine wave converters, but it seems that if we designed a half bridge that puts out a synth sine with a fictitious ground at 1/2 Vcc, we'd have one phase done. The next phase would be the same exact thing except the pattern offset by 120 degrees, and the next phase by another 120 degrees. But then the peaks would be limited to 1/2 Vcc rather than Vcc which we get with a single phase H bridge. So maybe we'd want to think about creating the pattern distinct from the single phase approach, unless maybe we're using an output transformer.

Not sure how you guys are approaching this here though. Maybe you can enlighten me.