Back when I was actually paid to sit on my butt in front of a computer for much of the day, I had a 40,000 sqft metal shop underneath my office. They were magicians, and I am permanently spoiled. I can do good enough panel work, but it is tedious.

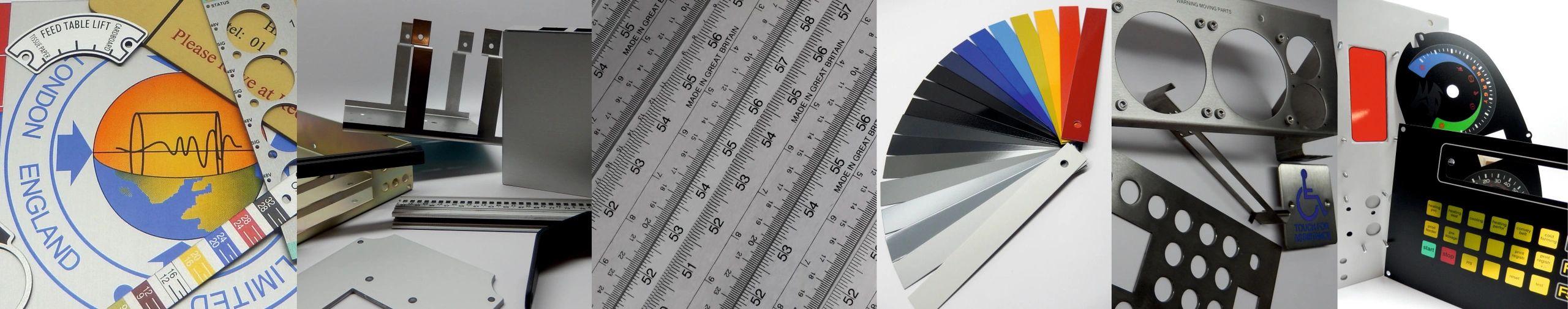

There have been several threads about low cost pcb fab shops. This question is about sheet metal shops. I have a variety of small and medium sized enclosures, and want to know if there is a pcb-equivalent for sheet metal. I'm after a semi-pro look for hobby projects. Very small lots, don't care about delivery delays, prefer low cost. There are places in town that can do this, but the costs are way high.

One option I have considered is having a pcb shop make the panels out of FR-4, but I'd like to stick with aluminum.

Thanks.

ak

There have been several threads about low cost pcb fab shops. This question is about sheet metal shops. I have a variety of small and medium sized enclosures, and want to know if there is a pcb-equivalent for sheet metal. I'm after a semi-pro look for hobby projects. Very small lots, don't care about delivery delays, prefer low cost. There are places in town that can do this, but the costs are way high.

One option I have considered is having a pcb shop make the panels out of FR-4, but I'd like to stick with aluminum.

Thanks.

ak