RaeyofLight

New Member

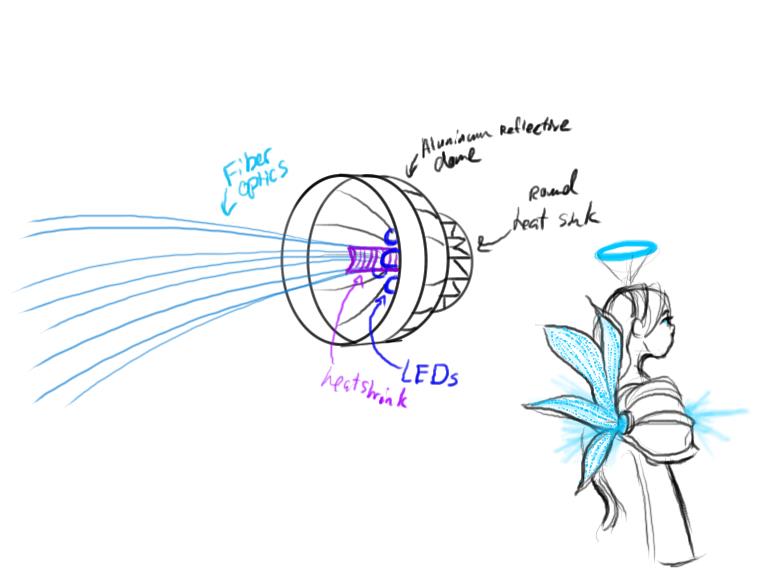

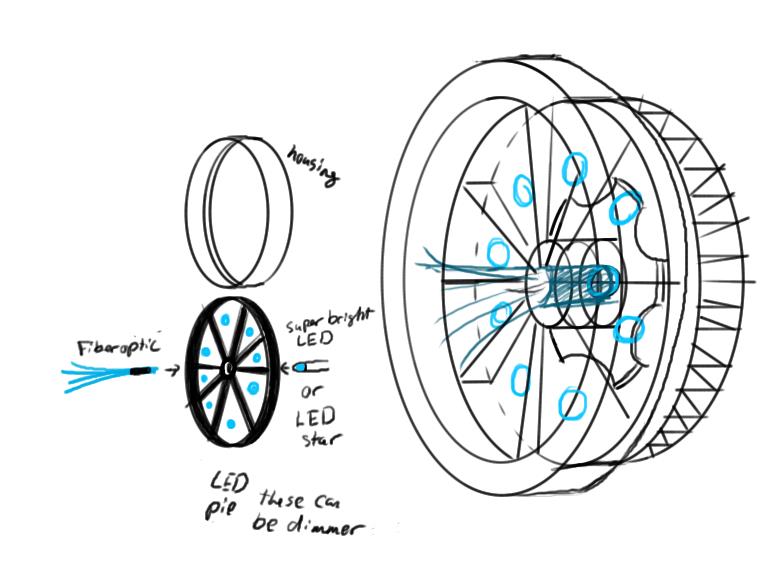

So I'm continuing a project I did last year where I created this costume for a convention. There is a 3D view on the page. We are going again so I am creating the shoulder pieces to go with it. There are ghostly wings that emanate from back LED and I was considering creating a wire fairy like wings with fiber optic fabric to attach to the back. However I don't know how I would go about constructing this since the back piece has its' own LED and how would I get light into the fabric from there. I'm not sure if I ought to like... have the Circular light board emanating out and use another smaller LED to shrink into the fabric?

I found this link which talks about getting a large amount of light to flood into the fabric... Seems dangerous tho if it needs fan. Other lights I found were

http://www.hobbyking.com/hobbyking/store/__28512__Blue_16_LED_Circular_Light_Board_with_Lead.html

I found this link which talks about getting a large amount of light to flood into the fabric... Seems dangerous tho if it needs fan. Other lights I found were

http://www.hobbyking.com/hobbyking/store/__28512__Blue_16_LED_Circular_Light_Board_with_Lead.html