Dear Experts

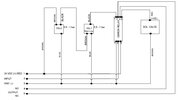

This is the first time i am posting thread in this Forum. I am a beginner w.r.t. electronics. I am using one circuit comprising of

1. Pressure Switches 2 Nos. connected in series (specifications attached)

2. Omron Relay 1 No. (G2R-2-SND DC24) 3. Solenoid Coil (24 V DC) 1 No.

The circuit is working fine. We supply components with this circuit within a panel. We have supplied numerous panel but in some of the panels we are facing a problem of failure of 1st Pressure Switch. As per our observation this problem occurs due to excessive current flown in circuit.

Can somebody help to resolve the above issue. Your assistance in this regard would be highly appreciated.

This is the first time i am posting thread in this Forum. I am a beginner w.r.t. electronics. I am using one circuit comprising of

1. Pressure Switches 2 Nos. connected in series (specifications attached)

2. Omron Relay 1 No. (G2R-2-SND DC24) 3. Solenoid Coil (24 V DC) 1 No.

The circuit is working fine. We supply components with this circuit within a panel. We have supplied numerous panel but in some of the panels we are facing a problem of failure of 1st Pressure Switch. As per our observation this problem occurs due to excessive current flown in circuit.

Can somebody help to resolve the above issue. Your assistance in this regard would be highly appreciated.