While I'm recovering from my second knee replacement, I had an interesting concept on creating enclosures without too much effort.

My designs tend to have a microcontroller board where all the work gets done and connections to the outside world are made and some kind of user interface board with a display and switches, usually connected by an I2C 6-wire interface. I saw an offer for extremely cheap circuit boards and started working on a new general purpose platform to try a few things out. What could possibly go wrong while chewing on pain pills?

The driving force behind this design is these "Hexalithus Fixed Block Acrylic Link Blocks" from Elecrow. These blocks are a 10mm cube, drilled and tapped for 3mm screws on every face. If a pair of circuit boards is designed with these blocks at each corner, the top, bottom and sides of the enclosure could be made from laser-cut 3mm acrylic. The cost of the needed 8 blocks alone is about US$9, but that's not outragous for a custom-design enclosure with a little style.

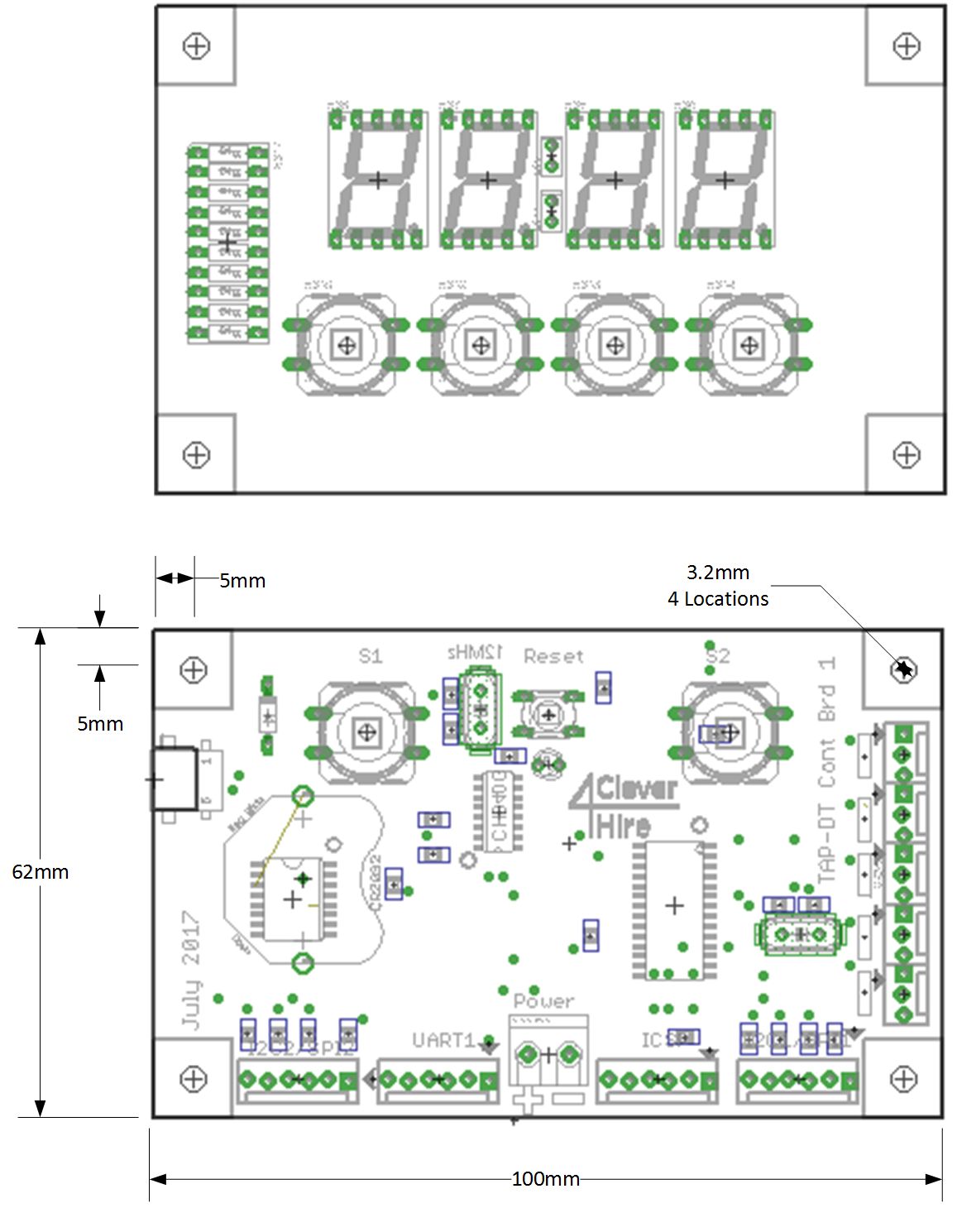

For this project, I'm picturing something like a digital clock. A four digit 7-segment readout, some other indicator LEDs and a few switches on the front panel with the rear panel having various connectors on the back to interface to various sensors or remote boards. It could display time, temperature or other sensor readings. This illustration shows the pair of boards. The control board is nearly complete while the front is just a rough idea so far. I followed Dangerous Prototype's Sick of Beige for the board dimensions.

I don't envision any fancy interconnect system between boards - just 6-pin and/or 3-pin jumpers as needed. For the 6-pin connectors, I follow Microchip's layout from the PICkit2 programmer/UART tool and the similar Serial Programmer. The function of the port pins varies, but all of my 6-pin headers are:

My 3-pin connectors are:

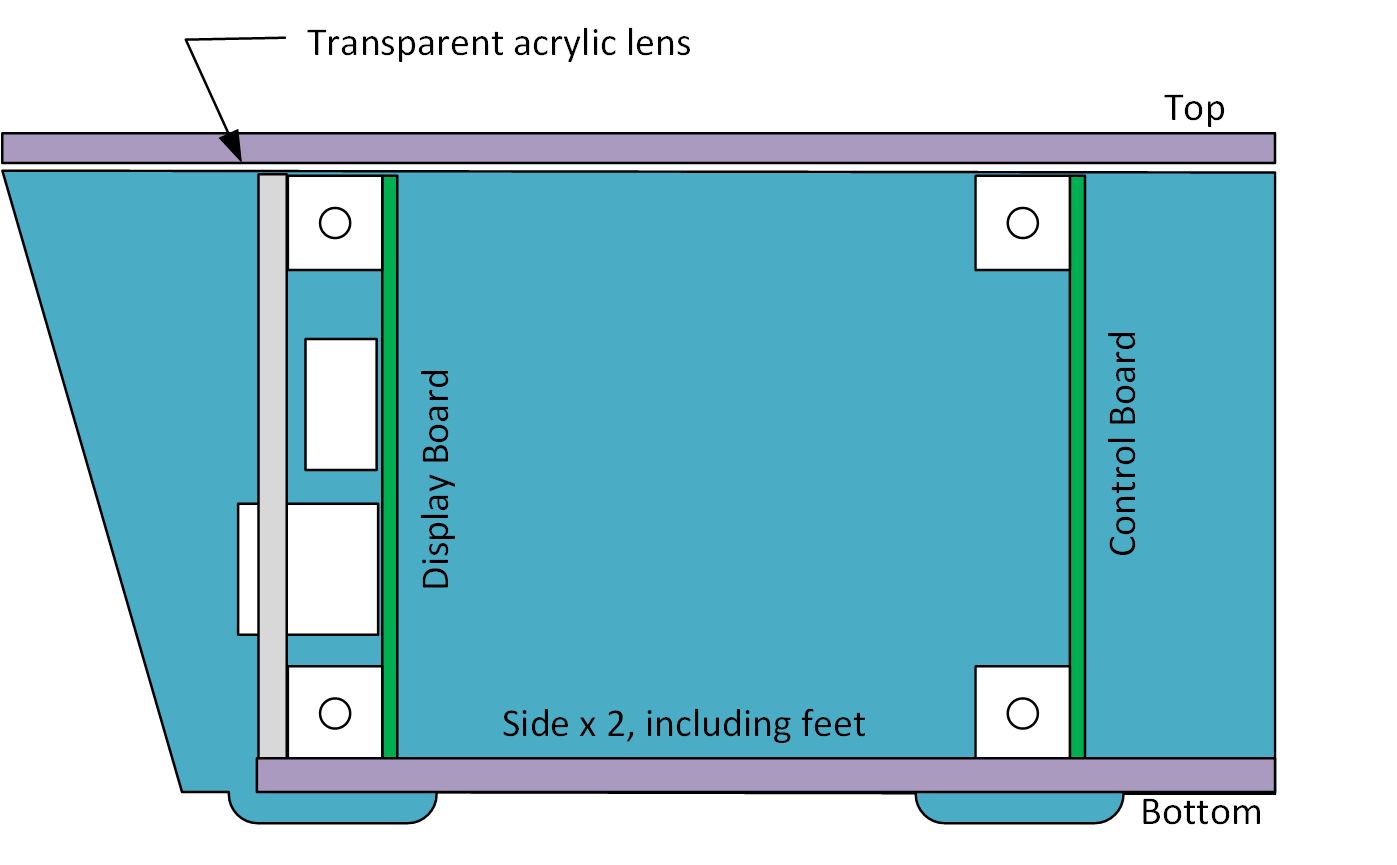

With the blocks at each board corner, laser-cut sides, top and board quickly assemble into an enclosure. This picture shows a little style with an overhang around the display to prevent glare, feet on the side panels (since screw heads will be exposed) and extended panels at the back to protect connections. The cubes on the user interface board provide for a transparent lens in front of LED digits or bargrapghs.

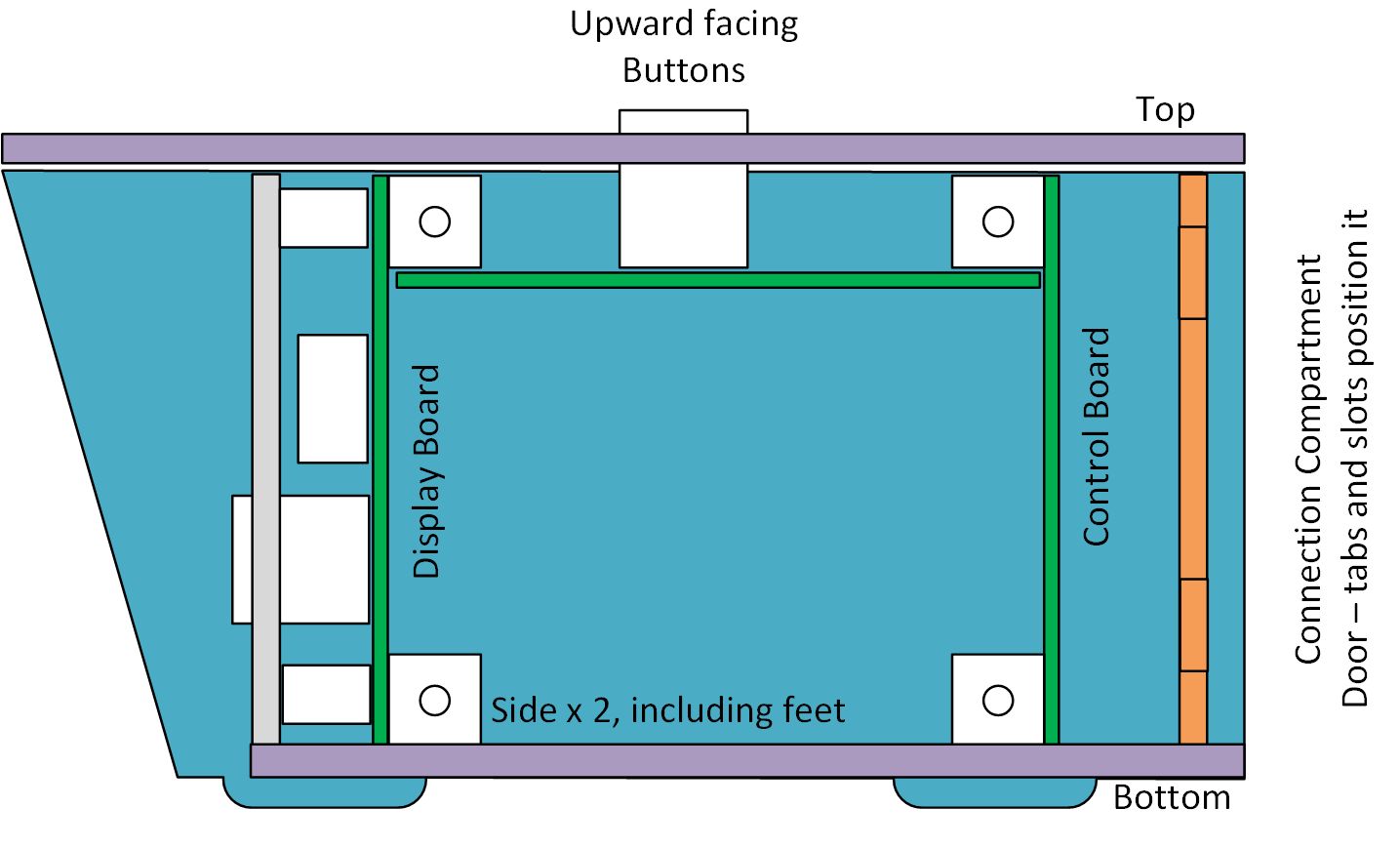

It's pretty easy to expand from here. For example, if upward facing switches are desired (think snooze button on a clock), a third circuit board could be supported horizontally under the top set of blocks. This would also be a good place to use one of those burn-your-eye non-diffused LEDs. A status indicator shining on the ceiling would be easy to see from any place in the room. Using a horizontal board requires repositioning the blocks on the front board but 3mm standoffs will support a lens in their place.

If an enclosed connection area is desired, a rear panel can be added using tabs and slots in the acrylic pieces to lock it into position.

Using this method, the length of the enclosure (distance between front and rear boards) can be anything you like. Additional boards may be supported using standoffs on the blocks if desired and the length can be increased to accomodate a battery pack. Compared to standard acrylic tab and slot construction, this enclosure will hold together - the top or side panel may be removed for access without everything falling apart.

My designs tend to have a microcontroller board where all the work gets done and connections to the outside world are made and some kind of user interface board with a display and switches, usually connected by an I2C 6-wire interface. I saw an offer for extremely cheap circuit boards and started working on a new general purpose platform to try a few things out. What could possibly go wrong while chewing on pain pills?

The driving force behind this design is these "Hexalithus Fixed Block Acrylic Link Blocks" from Elecrow. These blocks are a 10mm cube, drilled and tapped for 3mm screws on every face. If a pair of circuit boards is designed with these blocks at each corner, the top, bottom and sides of the enclosure could be made from laser-cut 3mm acrylic. The cost of the needed 8 blocks alone is about US$9, but that's not outragous for a custom-design enclosure with a little style.

For this project, I'm picturing something like a digital clock. A four digit 7-segment readout, some other indicator LEDs and a few switches on the front panel with the rear panel having various connectors on the back to interface to various sensors or remote boards. It could display time, temperature or other sensor readings. This illustration shows the pair of boards. The control board is nearly complete while the front is just a rough idea so far. I followed Dangerous Prototype's Sick of Beige for the board dimensions.

I don't envision any fancy interconnect system between boards - just 6-pin and/or 3-pin jumpers as needed. For the 6-pin connectors, I follow Microchip's layout from the PICkit2 programmer/UART tool and the similar Serial Programmer. The function of the port pins varies, but all of my 6-pin headers are:

- Port Pin

- +5V

- GND

- Port Pin

- Port Pin

- Port Pin

My 3-pin connectors are:

- port pin

- +5V

- GND

With the blocks at each board corner, laser-cut sides, top and board quickly assemble into an enclosure. This picture shows a little style with an overhang around the display to prevent glare, feet on the side panels (since screw heads will be exposed) and extended panels at the back to protect connections. The cubes on the user interface board provide for a transparent lens in front of LED digits or bargrapghs.

It's pretty easy to expand from here. For example, if upward facing switches are desired (think snooze button on a clock), a third circuit board could be supported horizontally under the top set of blocks. This would also be a good place to use one of those burn-your-eye non-diffused LEDs. A status indicator shining on the ceiling would be easy to see from any place in the room. Using a horizontal board requires repositioning the blocks on the front board but 3mm standoffs will support a lens in their place.

If an enclosed connection area is desired, a rear panel can be added using tabs and slots in the acrylic pieces to lock it into position.

Using this method, the length of the enclosure (distance between front and rear boards) can be anything you like. Additional boards may be supported using standoffs on the blocks if desired and the length can be increased to accomodate a battery pack. Compared to standard acrylic tab and slot construction, this enclosure will hold together - the top or side panel may be removed for access without everything falling apart.