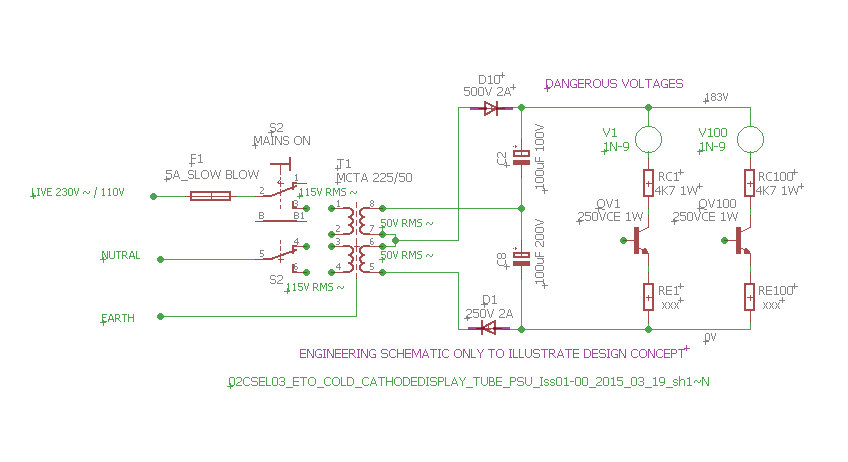

UPDATE: 04 of 2016_04_10 THIS SCHEMATIC IS NOW REPLACED BY ISSUE 2 SHOWN IN POST 155

ERRATA

(1) Add a 100nf min 400V min ceramic capacitor across the 183V supply rail for every five cold cathode indicator tubes

(2) C2 and C8 should be 3300uF (3m3F) for the full complement of 100 tubes. C2 and C8 can be scaled according to the number of tubes used but the minimum value is 100uF.

(3) The specified transformer has 55V secondary windings not 50V as indicated on the schematic.

(4) As a result of (3) above the 183V line will be 231V off load.

(5) The transformer is changed to type MCTA 120/55 (also shown on the data sheet below)

NOTES

(1) The circuit can be simplified if a 120WH minimum transformer with a 150V RMS secondary can be located.

(2) IN-9 cold cathode display tube salient characteristics:

(2.1) ionizing voltage: 70V

(2.2) striking voltage: 140V

(2.3) maximum current: 12 mA

(3) All capacitor values can be increased provided the type is maintained.

(4) capacitors can be connected in parallel to make up a value but capacitors should not be connected in series.

(5) The 183V supply is isolated from the mains supply.

(6) With 1.2A current drain (100* 12 mA) there will be around 14V peak to peak ripple on the 183V supply line.

(7) for optimum light control, transistors VT1 to Vt100 should be configured as linear current sinks.

(8) The IN-9s will be dissipating around 840mW so they should be in a position where air can flow freely around them.

LINKS

(1) Mains Transformer

https://cpc.farnell.com/multicomp/mcta225-55/transformer-225va-2x-55v/dp/FF01588

(1) Add a 100nf min 400V min ceramic capacitor across the 183V supply rail for every five cold cathode indicator tubes

(2) C2 and C8 should be 3300uF (3m3F) for the full complement of 100 tubes. C2 and C8 can be scaled according to the number of tubes used but the minimum value is 100uF.

(3) The specified transformer has 55V secondary windings not 50V as indicated on the schematic.

(4) As a result of (3) above the 183V line will be 231V off load.

(5) The transformer is changed to type MCTA 120/55 (also shown on the data sheet below)

NOTES

(1) The circuit can be simplified if a 120WH minimum transformer with a 150V RMS secondary can be located.

(2) IN-9 cold cathode display tube salient characteristics:

(2.1) ionizing voltage: 70V

(2.2) striking voltage: 140V

(2.3) maximum current: 12 mA

(3) All capacitor values can be increased provided the type is maintained.

(4) capacitors can be connected in parallel to make up a value but capacitors should not be connected in series.

(5) The 183V supply is isolated from the mains supply.

(6) With 1.2A current drain (100* 12 mA) there will be around 14V peak to peak ripple on the 183V supply line.

(7) for optimum light control, transistors VT1 to Vt100 should be configured as linear current sinks.

(8) The IN-9s will be dissipating around 840mW so they should be in a position where air can flow freely around them.

LINKS

(1) Mains Transformer

https://cpc.farnell.com/multicomp/mcta225-55/transformer-225va-2x-55v/dp/FF01588

Last edited: