NorthGuy

Well-Known Member

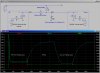

I looked up information and sample circuits of DS18S20 temerature sensors connected to PIC microcontrollers, such as this one. They show the schematics where PIC's pin is connected directly to the sensor with pullup resistor to VDD. There are many and all seem the same, including manufacturer's application notes. They all don't mind using longer wires, sometimes 300 ft or longer, and only recommend using smaller (less resistance) pullup resistors as the cable gets longer.

The problem I see with this is that the PIC's output pins are rated for 50 pF capacitive load, while cables typically have capacitance of 12 pF/ft. So, 30 ft cable that I'm going to use will be 360 pF, maybe more. When connected directly to the pin, it'll be over 7 times the maximum allowable capacitive load, and must be harmful/destructive to the PIC. With 300 ft, you get 3600 pF! Still, everyone connects it that way.

How people can use such long cables without worrying about harmful effects of high capacitive load?

The problem I see with this is that the PIC's output pins are rated for 50 pF capacitive load, while cables typically have capacitance of 12 pF/ft. So, 30 ft cable that I'm going to use will be 360 pF, maybe more. When connected directly to the pin, it'll be over 7 times the maximum allowable capacitive load, and must be harmful/destructive to the PIC. With 300 ft, you get 3600 pF! Still, everyone connects it that way.

How people can use such long cables without worrying about harmful effects of high capacitive load?