ADWSystems

Member

For one of the newest prototypes, I need a "discrete" pot. Basically a rotary switch changing the selected resistors (8 values total). The idea is to increase current draw in known steps (8 total) using 100 ohm resistors. The simpliest thing would be to connect an increasing number of resistors in parallel at the contact on the switch (ie., 1 on the first, two on the second, three on the third, etc.). That would add to 32 resistors, some could be reduced if the resistors in parallel equate to a typically available value.

One thought was to use a string of 8 resistors and select where in the ladder I enter the circuit would determine the resistance, but the values are too close together and not readily available or produced. The resistor values for this would be 11.1, 1.4. 1.8, 2.4, 3.3, 5, 8.3, 16.7, and 50; none of which are readily available and all are very close together.

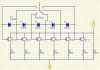

I also thought of using diodes on the switch. So the 8 100 ohm resistors would be in parallel connected by diodes at the top to each position on the switch. When position 2 was selected, current would flow directly through R2 and through a diode to contact 1 and down through R1, but that ends up incorporating a successive number of diodes in series as the dial is increased (position 3 would go through two diodes to get to R1, etc.).

If you can follow my word scramble, I would love to hear your brainstorms.

One thought was to use a string of 8 resistors and select where in the ladder I enter the circuit would determine the resistance, but the values are too close together and not readily available or produced. The resistor values for this would be 11.1, 1.4. 1.8, 2.4, 3.3, 5, 8.3, 16.7, and 50; none of which are readily available and all are very close together.

I also thought of using diodes on the switch. So the 8 100 ohm resistors would be in parallel connected by diodes at the top to each position on the switch. When position 2 was selected, current would flow directly through R2 and through a diode to contact 1 and down through R1, but that ends up incorporating a successive number of diodes in series as the dial is increased (position 3 would go through two diodes to get to R1, etc.).

If you can follow my word scramble, I would love to hear your brainstorms.